Introduction:

In the dynamic landscape of technology, Artificial Intelligence (AI) is not only a disruptive force but a catalyst for innovation across various industries, including semiconductor industry.

In 2023, AI is playing a pivotal role in revolutionizing chip design, optimizing manufacturing processes, and fostering the development of cutting-edge applications. This blog post delves into the intricate ways AI is reshaping the semiconductor landscape and highlights specific examples of its impact.

3 Ways Artificial Intelligence (AI) is Revolutionizing Semiconductor Industry

1. Revolutionizing Chip Design:

a. Automation for Faster Design Cycles:

AI is emerging as a game-changer in chip design by automating critical aspects. Tools developed by companies like Synopsys and Cadence Design Systems leverage AI algorithms to automate placement and routing, significantly reducing design cycles. The result is faster time-to-market for semiconductor products.

b. Layout Generation and Power Optimization:

The ability of AI to automatically generate layouts and optimize power consumption is a paradigm shift in chip design. This not only streamlines the design process but also contributes to cost reduction and improved performance. Designers can focus more on innovation and less on mundane tasks, fostering creativity in semiconductor development.

c. Error Verification:

AI algorithms are adept at error verification in chip designs. By automating the process of identifying and rectifying errors, AI ensures the production of high-quality semiconductor chips. This contributes to increased reliability and decreased chances of defects in the final products.

Read More: 3 Ways Synopsys and Cadence are Using AI in their EDA tools

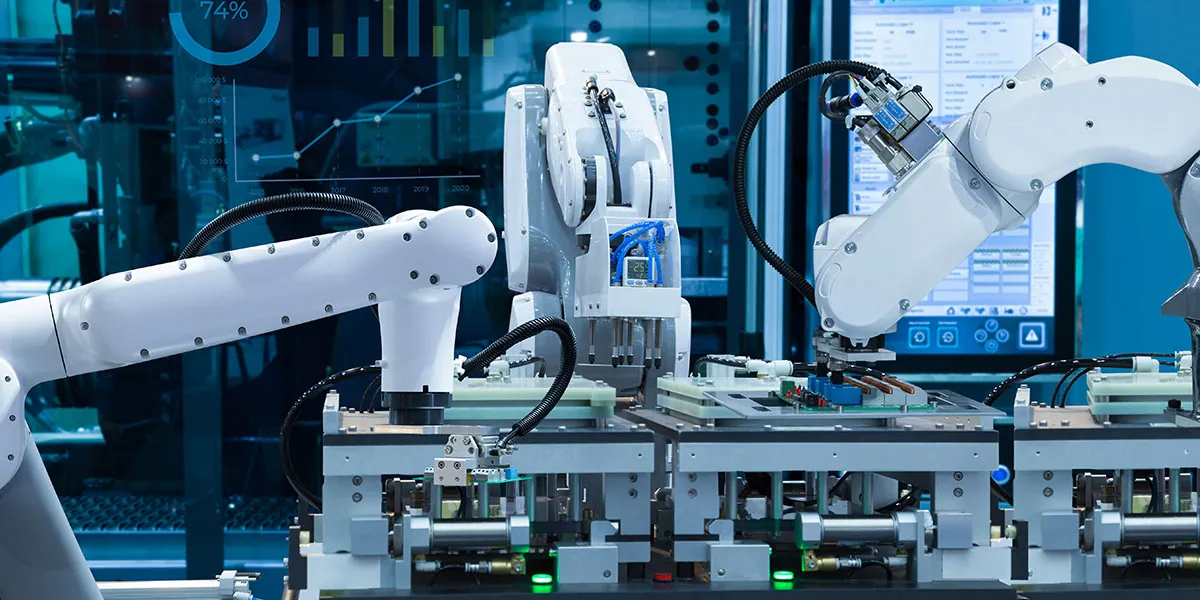

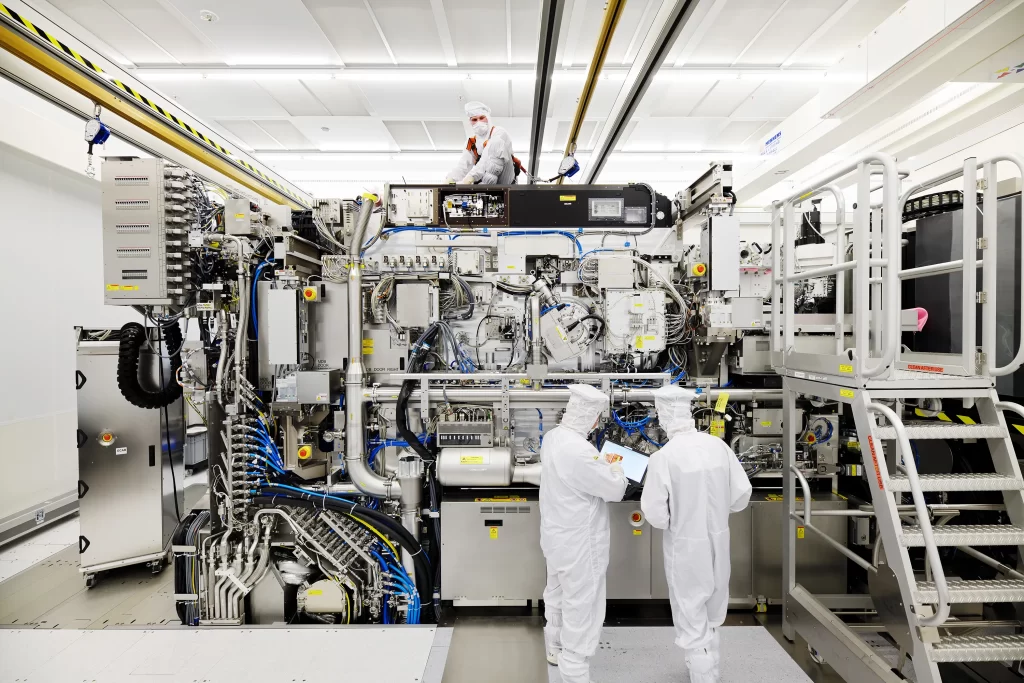

2. Optimizing Manufacturing:

a. Process Control and Yield Management:

In semiconductor manufacturing, AI is optimizing processes by providing real-time analysis of data from various sources, including sensors. Companies like Applied Materials and KLA Tencor utilize AI for yield management, identifying and addressing issues during wafer fabrication processes. This enhances overall production efficiency and contributes to improved yields.

b. Predictive Maintenance:

AI’s predictive capabilities are harnessed for maintenance in semiconductor factories. By analyzing data from equipment sensors, companies like Siemens and GE predict potential failures, enabling preventive maintenance. This proactive approach reduces downtime, enhances equipment longevity, and contributes to cost savings.

3. Developing New Applications:

a. AI-Enabled Specialty Chips:

The surge in AI-powered applications like autonomous vehicles, smart cities, and the Internet of Things (IoT) demands specialized chips. AI plays a crucial role in designing and developing these chips, ensuring they meet the unique requirements of emerging technologies.

b. AI in the Semiconductor Industry:

AI is not only transforming external applications but also influencing the semiconductor industry itself. Companies are employing AI to create advanced tools and applications, fostering continuous innovation within the sector.

Read More: How much Do you know Semiconductor Manufacturing

Specific Examples:

a. AI-Powered Chip Design Tools:

Companies like Synopsys and Cadence Design Systems are at the forefront of developing AI-powered tools for chip design, automating intricate processes such as placement and routing.

b. AI-Based Yield Management:

Applied Materials and KLA Tencor utilize AI to analyze data from wafer fabrication processes, addressing yield issues and optimizing production efficiency.

c. AI-Powered Predictive Maintenance:

Siemens and GE leverage AI to predict equipment failures, enabling preventive maintenance in semiconductor factories and minimizing downtime.

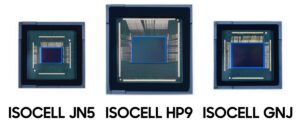

d. AI-Powered Defect Detection:

Semiconductor giants like Samsung and SK Hynix employ AI for defect detection in semiconductor wafers, enhancing yield and product quality.

Read More: What are Top 10 Countries with the Cheapest Manufacturing Costs in 2023

Conclusion:

The impact of AI on the semiconductor sector is undeniable, and its influence is set to grow exponentially in the coming years. From revolutionizing chip design and optimizing manufacturing to enabling the development of innovative applications, AI is a driving force behind the continuous evolution of the semiconductor industry. As technology advances, the synergy between AI and semiconductors will likely unlock unprecedented possibilities, propelling us into a new era of technological achievement.