Step into the shoes of Jane, a process engineer at GlobalFoundries, as she navigates a day filled with unexpected challenges in the world of semiconductor manufacturing.

In his cleanroom suit, Rajesh was engrossed in reviewing the day's production schedule when an urgent call pierced the morning calm. The lithography machine was malfunctioning, and the layout for a crucial chip design was disastrously off. Panic started to set in among the operators on the production floor, fearing potential delays and customer dissatisfaction.

When a critical problem arises with a chip layout, Rajesh and his team embark on a relentless pursuit to resolve it, revealing the dedication and ingenuity required to thrive in this high-tech world.

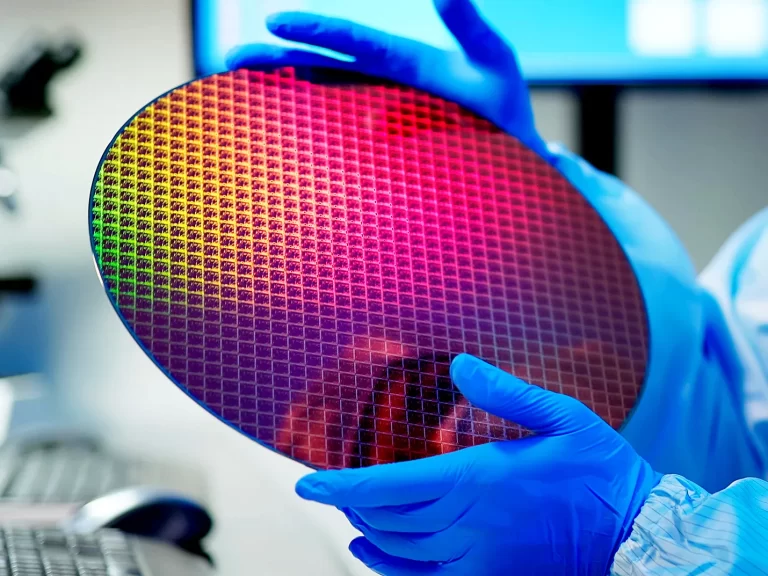

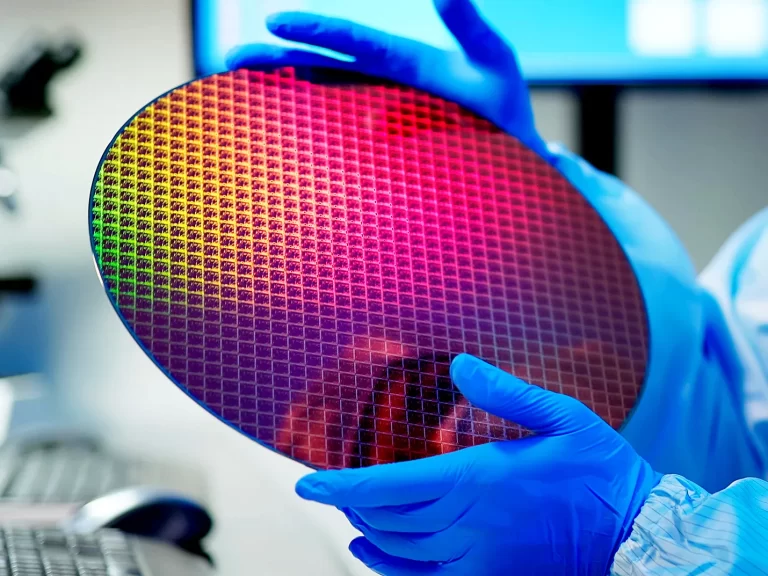

The sun painted the sky with hues of pink and orange as Rajesh stepped into the state-of-the-art VLSI fab. He knew that every day brought a new challenge, but this particular morning carried an air of urgency. As he sipped his morning chai, an alert on his phone caught his attention - a troubling anomaly during the etching process on advanced 7nm wafers.

As I began my day as a layout verification engineer, the anticipation of a new project was high. Little did I know that it would start with a daunting conflict that would put my skills and determination to the test. Opening my email, my heart sank upon seeing a message from my team lead, Priya, expressing dissatisfaction with a critical design layout I had verified the previous day.

In the ever-evolving landscape of technology, physical design engineers serve as the unsung heroes behind the scenes, shaping the heart and soul of modern semiconductor chips. Their expertise lies in the art of transforming logical designs into tangible layouts, pushing the boundaries of what's possible in the world of electronics.

Join us on a fascinating journey into the world of semiconductor manufacturing as we shadow Emily, a skilled Yield Enhancement Engineer. Discover the vital role she plays in optimizing processes and solving intricate yield issues to ensure top-quality chips are produced.

In the fast-paced realm of VLSI chip development, device engineers are at the forefront of innovation, tackling a wide array of complex challenges every day. Through this insightful narrative, we embark on a journey with a dedicated device engineer at a leading VLSI company, gaining a firsthand perspective on the intricacies of their work and problem-solving strategies.

The morning presents a formidable hurdle as I encounter an unexpected and complicated problem with one of my designs. The realization that the circuit fails a critical timing constraint leaves me determined to find a solution. Through meticulous analysis and collaboration with my team, we uncover the root cause of the issue and brainstorm innovative approaches to overcome it.

As the sun rises over the horizon, I prepare myself for another exciting day as a fab engineer in the bustling world of semiconductor manufacturing. Stepping into the cleanroom, I don my bunny suit, knowing that maintaining a pristine environment is crucial to ensuring the quality of the chips we produce.

With a cup of coffee in hand, I settle into my workstation, ready to review the production data from the previous day. Analyzing the numbers, I meticulously scrutinize for any irregularities or deviations. Today looks promising, but I notice a slight dip in yield on one of the processes. I make a mental note to investigate this further during the day.