Introduction

The rapid advancement of semiconductor technology has been a cornerstone of modern innovation, driving progress in everything from consumer electronics to cutting-edge scientific research. However, as the demand for microchips continues to surge, so too does the environmental impact of their production. A recent study by Interface has highlighted critical concerns regarding the ecological footprint of chip manufacturing, particularly in light of the ambitious goals set by the EU Chips Act.

Read More: Why GlobalFoundries Abandoned the Sub-7 nm Race: A Detailed Analysis – techovedas

Emissions Surge: The Potential Environmental Fallout

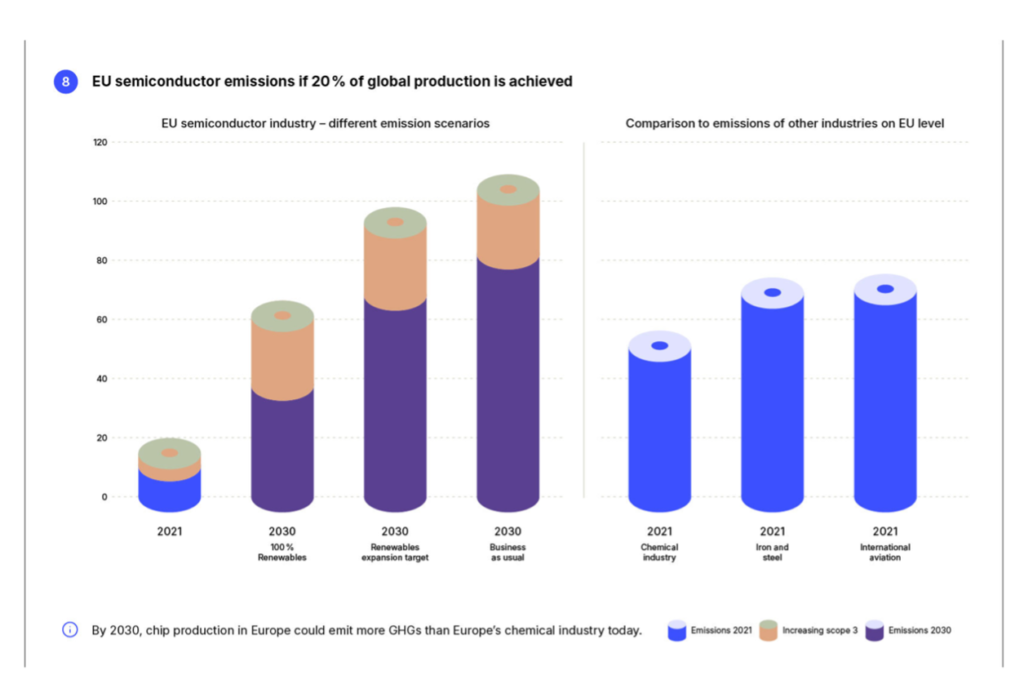

The EU Chips Act aims to position Europe as a global leader in semiconductor production, targeting 20% of global chip manufacturing by 2030. While this initiative promises significant economic and technological benefits, it also poses substantial environmental risks.

According to Interface’s study, achieving this production target could result in an up to eightfold increase in emissions, surpassing those from other emission-heavy industries such as steel and cement production.

This alarming projection underscores the pressing need to address the climate implications of expanding chip manufacturing capabilities.

Environmental Hotspots in Chip Production

The study by Interface identifies several key areas within the chip production process that contribute significantly to environmental degradation. These “hotspots” require targeted sustainability efforts to mitigate their impact:

Water Usage: Semiconductor manufacturing is highly water-intensive, requiring ultra-pure water for cleaning wafers after each layer addition. Leading chipmakers like Taiwan’s TSMC and US-based Intel consume vast quantities of water daily—193,000 tonnes and 161,000 tonnes, respectively. This level of consumption poses a significant challenge, particularly in regions facing water scarcity.

Energy Consumption: The energy demands of chip fabrication are substantial, contributing to the industry’s considerable carbon footprint. Reducing energy consumption through efficiency improvements and renewable energy integration is crucial for sustainable growth.

Waste Generation: The production of semiconductors generates significant waste, including hazardous materials that require careful disposal. Effective waste management strategies are essential to minimize the ecological footprint of chip manufacturing.

Chemical Usage: The use of chemicals in processes such as etching and cleaning impacts both water quality and air emissions. Implementing practices that reduce chemical usage and ensure proper disposal is vital for environmental protection.

Supply Chain Impact: The semiconductor supply chain, encompassing raw materials, equipment, and transportation, also contributes to the industry’s environmental impact. A holistic approach to sustainability must consider the entire supply chain.

Sustainable Practices for Greener Chip Manufacturing

To address the environmental challenges associated with chip production, semiconductor companies must adopt sustainable practices. Here are several strategies to enhance sustainability in the industry:

Renewable Energy: Transitioning to renewable energy sources such as solar and wind power can significantly reduce carbon emissions. Companies like TSMC and Intel are already investing in renewable energy to power their facilities, setting a precedent for the industry.

Water Recycling: Implementing advanced water recycling technologies helps conserve water resources. Reusing water in manufacturing processes reduces waste and mitigates the environmental impact of high-water consumption.

Eco-Friendly Materials: Selecting environmentally friendly materials for chip production can lower electronic waste and promote a circular economy. Exploring alternatives to traditional materials is a step towards greener manufacturing.

Efficient Packaging: Streamlining packaging processes to minimize waste and optimizing transportation logistics can reduce the carbon footprint of semiconductor products. Efficient packaging practices are crucial for sustainability.

Read More: Why GlobalFoundries Abandoned the Sub-7 nm Race: A Detailed Analysis – techovedas

Integrating Sustainability with Technological Progress

As the semiconductor industry continues to grow, balancing technological advancement with environmental sustainability is imperative.

The ecological footprint of chip production intersects with the goals of the EU’s Green Deal, highlighting the need to address climate concerns while fostering innovation.

A holistic approach to sustainability involves not only greener production practices but also energy-efficient deployment of chips in various systems.

Efforts by companies like TSMC, which has implemented a wastewater treatment plant, and Intel, which has launched numerous sustainability initiatives, demonstrate the industry’s potential to mitigate its environmental impact.

However, achieving meaningful change requires collective action and a commitment to integrating sustainable practices across the entire semiconductor supply chain.

Follow us on Linkedin for everything around Semiconductors & AI

Conclusion

The Interface study underscores the critical importance of addressing the environmental impact of chip production.

As the EU Chips Act drives the expansion of semiconductor manufacturing, it is essential to prioritize sustainability and mitigate the industry’s ecological footprint.

By adopting renewable energy, water recycling, eco-friendly materials, and efficient packaging, the semiconductor industry can balance technological progress with environmental responsibility. Together, we can create a more eco-conscious future for chip manufacturing, ensuring that innovation does not come at the expense of our planet.