Introduction

Over time, legacy or mature nodes have evolved through continuous refinement of manufacturing processes, enabling the production of chips with improved performance, efficiency, and reliability. Despite the ongoing advancements in semiconductor technology, there is a persistent need for legacy nodes in industry applications, their cost-effectiveness, and their compatibility with newer technologies.

In this article, we aim to explain why legacy nodes remain important today, even as companies strive to reach the 1nm technology node.

Follow us on Linkedin for everything around Semiconductors & AI

What are technology nodes?

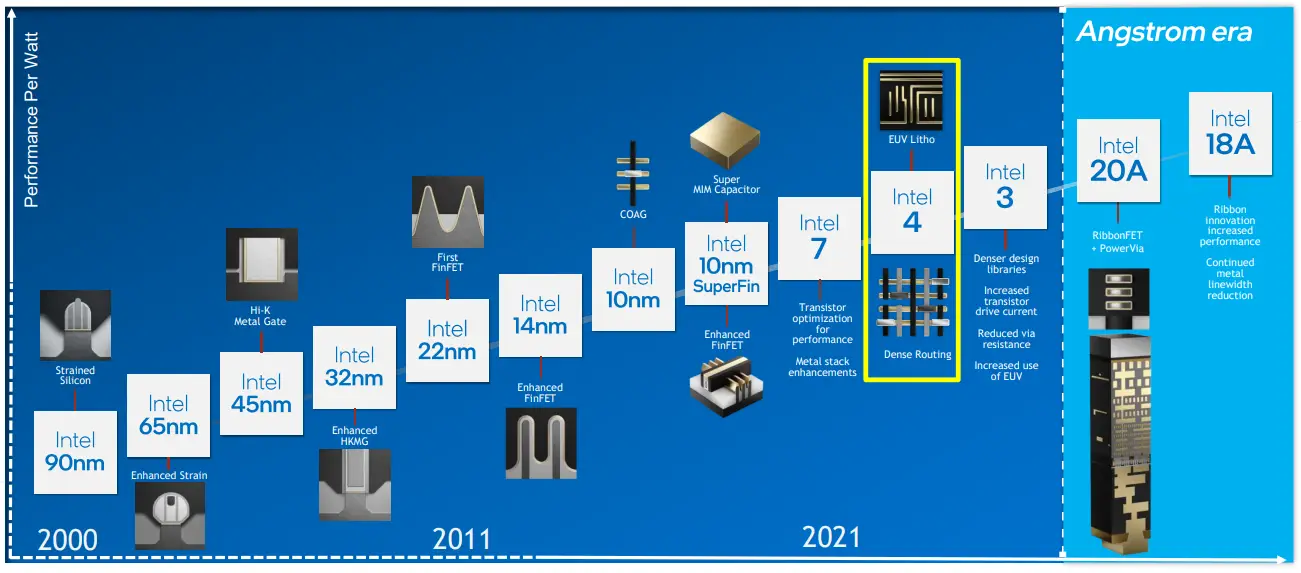

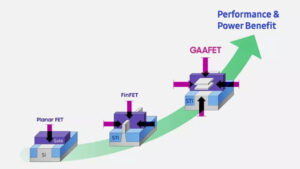

Essentially, technology node corresponds to the physical feature size of the transistor. Originally, every microcontroller is built out of transistors, which are basically switches which control the flow of electric current and allow the microcontroller to perform its logical function.

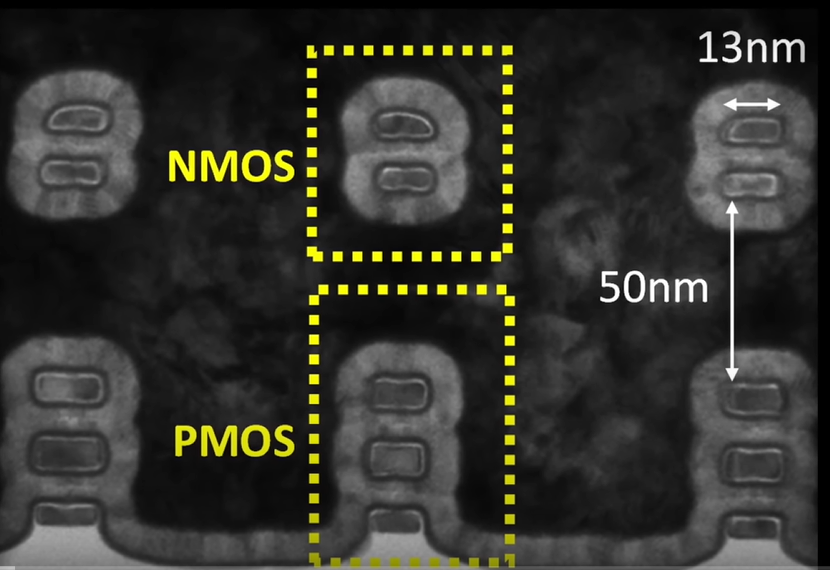

Technology nodes such as 28 nm or 65 nm are referring to the minimum data graphic feature which can be drawn on the layout (half pitch or gate length). However, there is no standardization in naming of technology nodes.

The name of a node such as 28 nm or 65 nm is actually coming from the minimum gate length of the transistor as shown in the conventional planar MOSFET configuration.

Read more What are Technology Nodes? – techovedas

What are legacy nodes?

Nodes with transistor feature sizes above 28nm are considered legacy nodes. These refer to well-established semiconductor manufacturing processes. Moreover,they have been optimized for mass production. Legacy nodes typically have larger transistor feature sizes, such as 45nm and 28nm. They are used to produce a wide range of integrated circuits. These circuits are common in consumer electronics, automotive, and industrial products.

Read More: AI on Steroids: Microsoft Unveils Copilot+ PCs with Built-in Generative AI Capabilities – techovedas

What makes legacy nodes important?

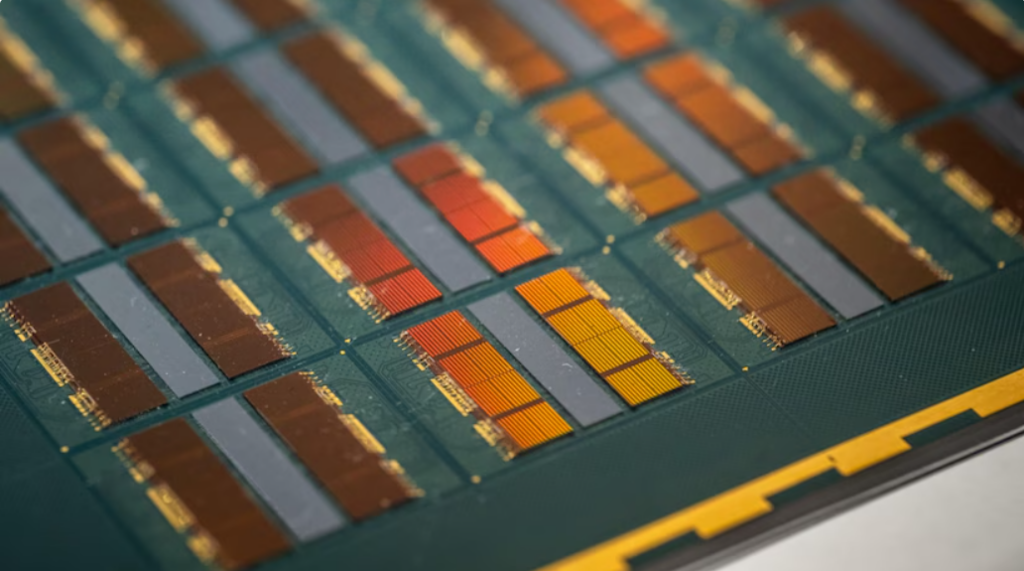

Chips manufactured at mature nodes typically fall under the radar, but they are used in nearly every electronic device, including appliances, cars, computers, displays, industrial equipment, smartphones, and TVs.

- Automotive: Legacy nodes are prevalent in automotive electronics for applications like engine control units (ECUs), infotainment systems, and driver assistance systems. These chips provide reliability and stability crucial for automotive operations.

- Industrial Control Systems: Legacy nodes are often used in industrial control systems for manufacturing equipment, process automation, and monitoring systems. Their proven reliability makes them ideal for ensuring stable operation in industrial environments.

- Consumer Electronics: Some consumer electronics devices, especially those that do not require the latest technology advancements, use legacy nodes. Examples include certain types of home appliances, legacy gaming consoles, and basic electronics gadgets.

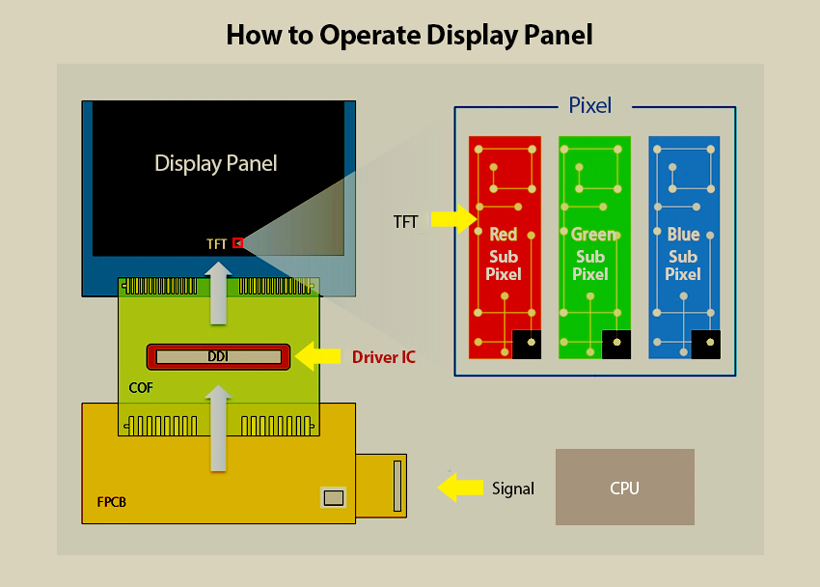

- Power management IC and display driver IC: Display driver ICs (DDICs) and power management ICs (PMICs) are also in tight supply. DDICs are used to power up a flat-panel display, while PMICs are geared to manage the power in systems.

We see applications related to power, such as PMICs and DDICs, in high demand, DDIC and PMIC production spans mature technologies from the 150nm through the 22nm/28nm nodes.”

UMC representative

Used in nearly every system, PMICs are chips that control the flow and direction of electrical power.

5. Aerospace and Defense: In aerospace and defense sectors, legacy nodes are often used in critical systems where reliability, longevity, and backward compatibility are essential. These chips power avionics, communication systems, radar systems, and missile guidance systems.

Impact of the 2022 Legacy Chip Shortage

Today’s widespread awareness of legacy chips was spurred by a shortage of chips during the Covid-19 pandemic.

Despite operating at historic output at that time, the domestic production base was not able to keep pace with domestic demand.

In early 2022, the U.S. Department of Commerce released the results of a survey addressing the chip shortage and found that firms faced their most acute shortages not in cutting-edge chips but in legacy chips at the 40 nm node or larger.

Most current U.S. chip production—and most global production—consists of these higher-node devices.

Read more Chip Shortages Continue for Mature Nodes – Impacting Multiple Industries – techovedas

Why ‘legacy’ is a misleading term?

The label “legacy semiconductors” implies they are outdated. It suggests that newer technologies will replace them. In reality, these semiconductors have important and enduring roles. They are crucial in energy production, memory storage, sensors, and more. Infineon’s Semiconductor Tree illustrates this. Schumaker stated that despite the “legacy” label, none of the branches are withering away. There are exciting, advanced developments in all those branches. These developments extend towards the leaves.

Benefits of Legacy nodes

- Better Yields: Legacy process nodes often have well-established manufacturing processes that have been optimized over time. This optimization leads to higher yields during production, reducing the number of defective chips and ultimately lowering production costs.

- Improved Reliability: Chips manufactured on legacy process nodes tend to be more reliable due to the maturity of the fabrication techniques used. The long history of these nodes allows for thorough testing and refinement, resulting in products that exhibit consistent performance and durability.

- Fewer Fabrication-steps: The simplicity and fewer production steps associated with legacy process nodes can reduce the likelihood of fabrication-related issues. With fewer complexities in the manufacturing process, there is a lower chance of defects or errors occurring during production.

Read more 10 Steps In Semiconductor Manufacturing – techovedas

Conclusion

Legacy nodes remain essential in the semiconductor industry. They offer cost-effectiveness, reliability, and compatibility with many applications. Despite advancements in technology, legacy nodes support critical sectors. These include automotive, industrial, consumer electronics, power management, and defense. They ensure stable and durable performance. The 2022 chip shortage highlighted the persistent demand for these mature technologies. This underscored their vital role in the global supply chain.