Background

India currently relies heavily on imports to meet its domestic demand for semiconductors, which poses a risk to its economic and national security for which a change is needed to create India’s Semiconductor Revolution.

According to a report by India Electronics and Semiconductor Association (IESA), India imported semiconductors worth $ 21.9 billion in 2020, accounting for 12.5% of its total electronics imports.

Moreover, the global semiconductor industry is facing a severe supply crunch due to the COVID-19 pandemic, geopolitical tensions, and rising demand from emerging technologies such as 5G, artificial intelligence, and electric vehicles. This has led to a surge in prices and a shortage of chips for various sectors, affecting India’s electronics manufacturing and digital transformation ambitions.

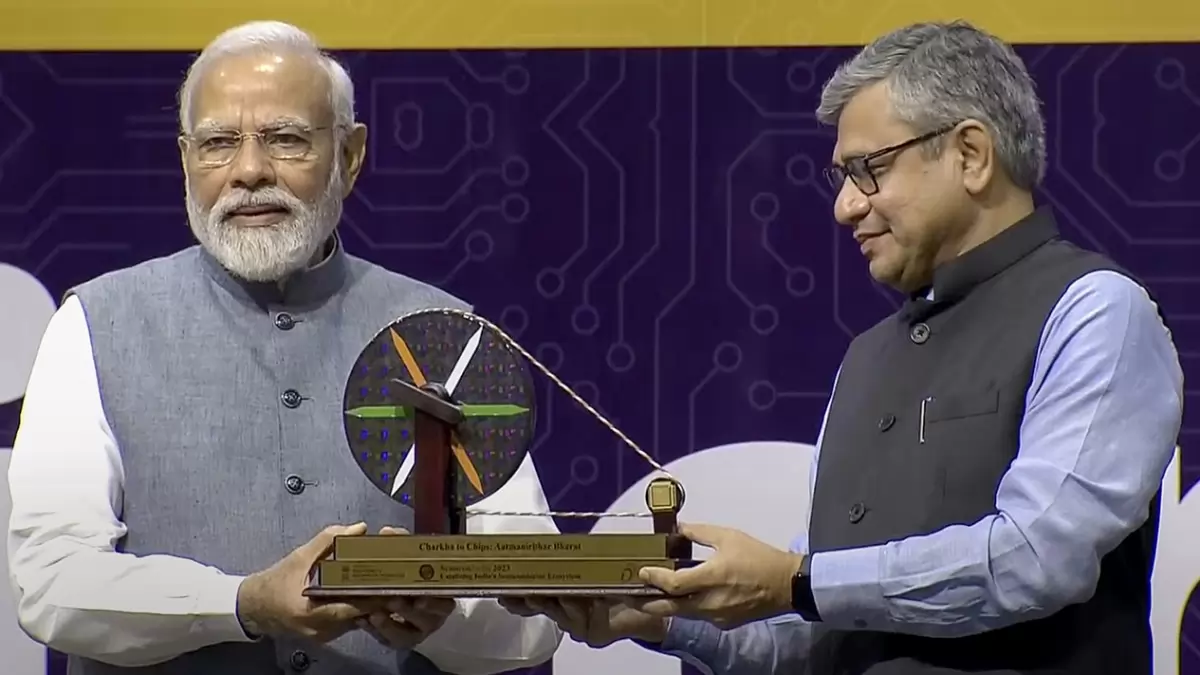

India’s Semiconductor Revolution

To address this challenge, the Indian government has launched an ambitious initiative to boost its domestic semiconductor and display manufacturing and design ecosystem. The initiative, called the India Semiconductor Mission (ISM), aims to

- Attract large investments,

- Create jobs,

- Reduce import dependence,

- Enhance India’s competitiveness and

- Promote innovation in the global semiconductor value chain.

The ISM is an independent business division within the Digital India Corporation, led by global experts from the semiconductor and display industry.

It serves as the nodal agency for the efficient and smooth implementation of four schemes under the Semicon India programme, which was approved by the Union Cabinet in December 2021 with a total outlay of Rs. 76,000 crore (>10 billion USD).

Read More: What is the Progress of Semiconductor Ecosystem in India in Last 2 years?

The four schemes are:

1. Scheme for setting up of Semiconductor Fabs in India

This scheme provides fiscal support of up to 50% of the project cost to eligible applicants for setting up of semiconductor wafer fabrication facilities in the country. The scheme covers different semiconductor nodes, ranging from 28nm or lower to 65nm or higher, depending on the technology and market requirements.

The scheme aims to attract investments of over Rs. 1.5 lakh crore and generate employment for over 1.5 lakh people.

2. Scheme for setting up of Display Fabs in India

This scheme provides fiscal support of up to 50% of the project cost, subject to a ceiling of Rs. 12,000 crores per fab, to eligible applicants for setting up of display fabrication facilities in the country.

The scheme covers different types of displays, such as TFT LCD and AMOLED, which are used in various devices such as TVs, monitors, smartphones, tablets, laptops, etc. The scheme aims to attract investments of over Rs. 40,000 crore and generate employment for over 50,000 people.

3. Scheme for building Niche and Emerging Semiconductor Facilities in India

This scheme provides fiscal support of 30% of the capital expenditure to eligible applicants for setting up of compound semiconductors, silicon photonics, sensors, and semiconductor ATMP / OSAT facilities (Outsourced Semiconductor Assembly and Test) in the country.

These facilities cater to the emerging and niche segments of the semiconductor industry, such as optoelectronics, power electronics, radio frequency, biotechnology, etc. The scheme aims to attract investments of over Rs. 15,000 crore and generate employment for over 25,000 people.

4. Design Linked Incentive (DLI) Scheme

This scheme offers financial incentives, design infrastructure support, and other benefits to eligible applicants for the development and deployment of semiconductor design for integrated circuits, chipsets, system on chips, systems, and IP cores.

The scheme covers different stages of the semiconductor design cycle, such as concept, feasibility, prototyping, testing, validation, and commercialization.

The scheme aims to promote indigenous IP generation, encourage technology transfer, and enable a multi-fold growth of the Indian semiconductor design industry.

ISM has invited applications from interested companies for setting up semiconductor and display fabs from June 1, 2023.

The ISM will also facilitate the adoption of trusted electronics through secure semiconductor and display supply chain. This will enable collaborations and partnerships with national and international agencies, industries and institutions. This will also support startups and MSMEs in the semiconductor and display ecosystem.

Read More: Tata to Produce iPhone for Indian & International Markets

Challenges on the road for India’s Semiconductor Revolution

– Lack of adequate infrastructure, such as power, water, land, logistics, etc., for setting up and operating semiconductor and display fabs

– Dependence on imports for raw materials, specialty chemicals, gases, and manufacturing equipment

– Shortage of skilled and experienced manpower

– Competition from other countries, such as China, South Korea, Taiwan, etc

– Protection of intellectual property rights, especially in the areas of semiconductor.

A bright future for India’s Semiconductor Revolution

India’s initiative, the India Semiconductor Mission (ISM), marks a crucial step in reducing the nation’s dependence on semiconductor imports.

With significant investments from global players, including Israel, Vedanta-Foxconn, Intel, and Micron, the ISM strives to bolster domestic manufacturing.

India is on the path to achieving self-sufficiency in semiconductor production, despite infrastructure challenges and global competition. This journey is laying the groundwork for technological autonomy in the country.