Introduction:

In the ever-evolving landscape of semiconductor technology, Applied Materials stands as a beacon of innovation, continually pushing the boundaries of what’s possible in chip manufacturing. At the recent SPIE Advanced Lithography + Patterning conference, the company unveiled its latest breakthrough: the Pioneer® XP CVD patterning film. This cutting-edge technology from AMat represents a significant leap forward in CVD, particularly in crucial areas such as DRAM scaling and EUV lithography.

Follow us on Linkedin for everything around Semiconductors & AI

AMAT CVD Background:

In DRAM (Dynamic Random Access Memory) production, one of the key challenges revolves around achieving precise feature dimensions during the manufacturing process. Feature dimensions refer to the various patterns and structures that need to be etched onto the semiconductor wafer to create the intricate circuitry of the DRAM chip.

These feature dimensions are critical because they directly impact the performance and functionality of the DRAM chips. For example, if the features are not etched accurately, it can lead to issues such as reduced chip functionality, lower performance, and even failure of the DRAM chip.

Image Credits: AMAT

One specific issue that arises in DRAM production is the need for improved etch selectivity and pattern fidelity. Etch selectivity refers to the ability to selectively remove certain materials from the wafer while leaving others intact. Pattern fidelity, on the other hand, refers to the accuracy and consistency with which the desired patterns are transferred onto the wafer during the etching process.

Traditionally, achieving high etch selectivity and pattern fidelity has been challenging due to several factors. These include variations in material properties, limitations of the etching tools, and the complexity of the patterning process itself. As semiconductor technology advances and feature sizes become smaller, these challenges become even more pronounced.

Failure to address these issues effectively can result in a range of problems, including yield losses, increased manufacturing costs, and decreased competitiveness in the market. Therefore, finding innovative solutions to improve etch selectivity and pattern fidelity is crucial for DRAM manufacturers to stay ahead in the highly competitive semiconductor industry.

Image Credits: AMAT

Empowering DRAM Scaling with AMAT CVD

Applied Materials’ Pioneer CVD (Chemical Vapor Deposition) patterning film addresses the challenge of achieving improved etch selectivity and pattern fidelity in DRAM production through several innovative features:

Enhanced Film Density and Stiffness:

Pioneer utilizes a unique high-density carbon formula that increases the film density and stiffness compared to traditional materials. This enhanced density and stiffness provide better resistance to etch chemistries used in advanced process nodes. As a result, Pioneer allows for thinner film stacks with superior sidewall feature uniformity.

Lower Aspect Ratios:

Thinner film stacks achieved with Pioneer result in lower aspect ratios during etching. Aspect ratio refers to the ratio of the depth of etched features to their width. Lower aspect ratios make it easier to etch precise features with finer control. Additionally, lower aspect ratios enable the use of lower-power plasma, which contributes to more efficient etches.

Image Credits: AMAT

Fine Control Over Ion-to-Radical Ratio:

Pioneer’s properties enable finer control over the ion-to-radical ratio during etching. This control is crucial for achieving precise etching and maintaining pattern fidelity. By optimizing the ion-to-radical ratio, Pioneer ensures that desired patterns are transferred to the wafer with exceptional fidelity, leading to improved overall performance and functionality of DRAM chips.

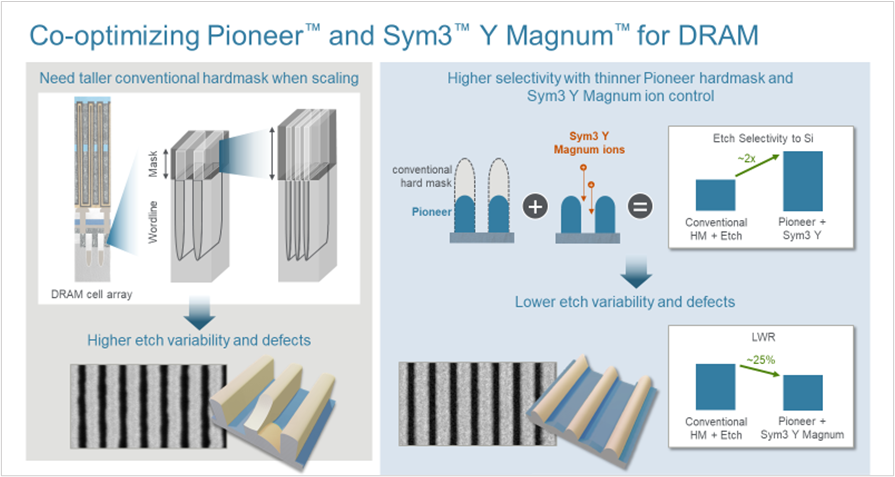

Co-Optimization with Etch Systems:

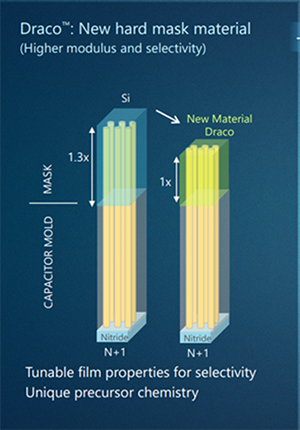

Applied Materials’ Pioneer is designed to work in synergy with other components of the semiconductor manufacturing process, such as the Draco™ hard mask and Sym3® Y HT etch system. This co-optimization ensures that Pioneer’s capabilities are fully leveraged to enable the etching of perfectly cylindrical capacitor holes, further improving etch selectivity and critical dimension uniformity in DRAM production.

In summary, Applied Materials’ Pioneer CVD patterning film enhances etch selectivity and pattern fidelity in DRAM production. It achieves this through enhanced film density and stiffness. Lower aspect ratios during etching are possible. Fine control over the ion-to-radical ratio is ensured. Co-optimization with other components of the manufacturing process is seamless. These features collectively enable semiconductor manufacturers to produce DRAM chips with higher precision, efficiency, and competitiveness in the market.

Addressing the Demands of EUV Lithography with AMAT CVD

In the realm of EUV (Extreme Ultraviolet) lithography, where precision is paramount, Pioneer shines bright. By increasing film density and stiffness, this advanced CVD patterning film enhances etch selectivity and allows for finer pattern control.

This is particularly vital in the ultra-fine dimensions required for advanced chip manufacturing. With Pioneer, semiconductor manufacturers can tackle the stringent demands of EUV lithography with confidence, knowing that they have the tools necessary to achieve unprecedented levels of precision and performance.

Read the Official Note from AMAT here

Industry Adoption and Future Prospects

Already, leading foundry-logic and memory manufacturers have embraced Pioneer for its advanced patterning capabilities. The adoption marks a move towards precise and efficient semiconductor manufacturing. This sets the stage for further advancements in the field. Applied Materials stays at the forefront, driving innovation and empowering the industry to reach new heights.

In conclusion, Applied Materials’ introduction of the Pioneer® XP CVD patterning film represents a significant milestone in semiconductor technology.