Introduction:

In the world of electronics, semiconductor Chips are the unsung heroes powering our technological marvels. Behind the scenes, a highly intricate and choreographed dance steps unfolds within the confines of a semiconductor fabrication facility, commonly known as a fab.

A complex facility known as a fab manufactures semiconductor devices. The process includes several steps, and we will provide a simplified overview using the example of a complementary metal-oxide-semiconductor (CMOS) process, a common method for producing integrated circuits (ICs) like microprocessors.

Follow us on Linkedin for everything around Semiconductors & AI

10 Fabrication Steps to Build a Semiconductor Chip

1. Design and Mask Creation:

The process begins with the design of the semiconductor device. Engineers create a detailed layout specifying the placement and interconnections of transistors, resistors, and other components.

Engineers use the design to create masks, serving as templates that define the patterns to transfer onto the semiconductor wafer during the manufacturing process.

Analogy: Imagine a master composer meticulously crafting a symphony. In the semiconductor world, engineers take on this role, designing the intricate layout of transistors, resistors, and interconnections. This design serves as the musical score, guiding the fabrication process. To bring this composition to life, engineers create masks – the conductor’s baton, directing each player (layer) to perform its part in harmony.

Read More: 10 Job Profiles in Semiconductor Chip Fabrication & Required Skill Sets

2. Wafer Preparation:

Engineers use silicon wafers as the substrate for semiconductor devices, undertaking the task of polishing and cleaning to eliminate any impurities. They then cultivate a thin layer of oxide on the wafer’s surface, establishing a smooth and uniform starting point for the subsequent process steps.

Analogy: Before the symphony begins, the stage must be set. Silicon wafers, akin to the pristine stage, are polished and cleaned to perfection. An oxide layer acts as the smooth canvas, ready to receive the musical notes that will define the semiconductor device’s functionality.

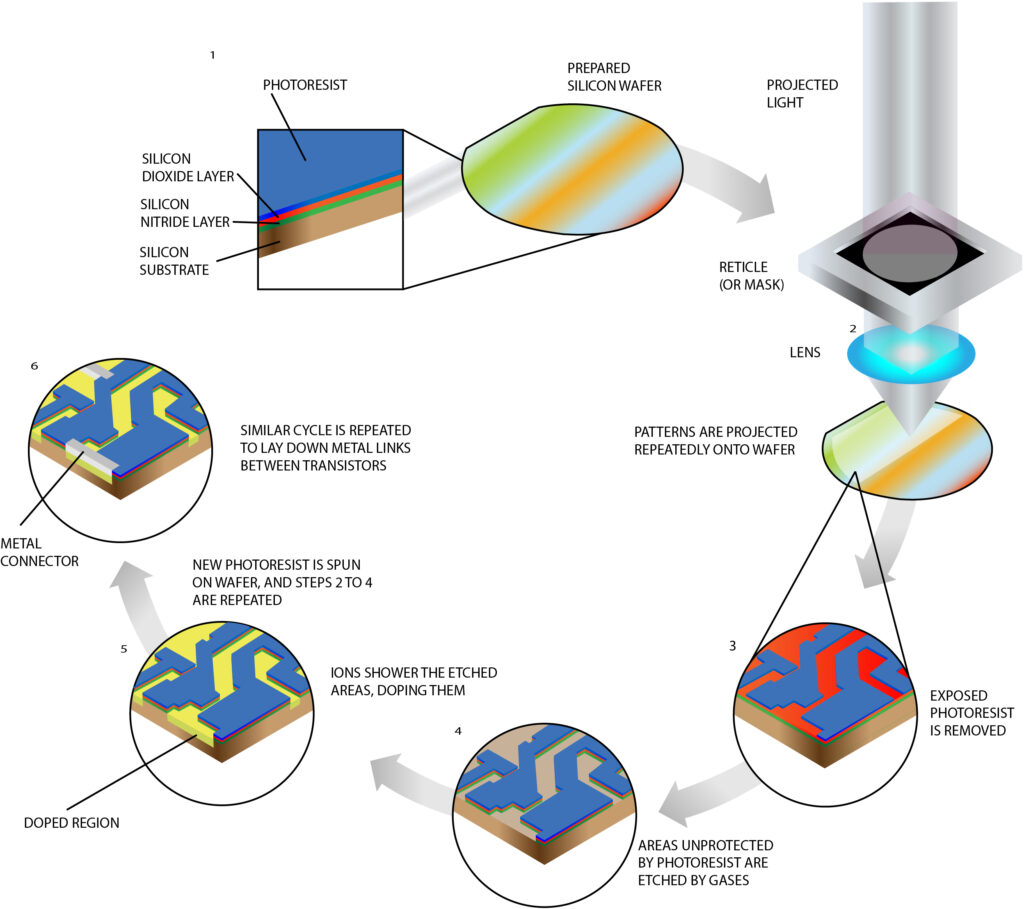

3. Photolithography:

In a process called photolithography, engineers use the masks created earlier. They apply a layer of photoresist to the wafer and place the mask over it. After exposing the wafer to light, the pattern from the mask is transferred onto the photoresist. They then develop either the exposed or unexposed areas, leaving a pattern on the wafer surface.

Analogy: Photolithography is the act of painting musical notes onto the stage. Applying masks as templates, engineers coat the wafer with a layer of photoresist, comparable to a canvas. Subsequently, they expose the stage to light, projecting the shadows of musical notes onto the photoresist. After development, engineers etch the notes into the wafer, defining the patterns that will shape the semiconductor’s components.

Read More: Purdue offers FREE 5-Hour Crash Course in Semiconductor Fabrication

4. Etching:

Etching is used to remove material from the wafer where the photoresist has been selectively removed. This step defines the features of the semiconductor device.

To create the desired patterns, engineers use different etching processes for various materials (e.g., silicon dioxide, polysilicon, metal layers).

Analogy: Just as a sculptor chisels away excess material to reveal a masterpiece, chemical etching removes unwanted material from the wafer. This step sculpts the features of the semiconductor device, shaping the melody that will resonate through the electronic symphony.

5. Deposition:

Techniques like chemical vapor deposition (CVD) or physical vapor deposition (PVD) deposit thin films of various materials, such as metal or insulating layers, onto the wafer surface.

These deposited layers create the conductive paths, insulating layers, and other elements of the semiconductor device.

Analogy: In the symphony of semiconductors, thin films of various materials are deposited onto the wafer, creating the harmonious layers that constitute the device. This is akin to the orchestra building up layers of sound, with each material playing its unique role in the composition.

Read More: Infineon is Building World’s Largest 200mm SiC Fab in Malaysia

6. Ion Implantation:

This step involves introducing dopant ions into specific regions of the wafer to modify its electrical properties. Ion implantation is crucial for creating the desired transistor characteristics.

Analogy: Just as a passionate soloist injects emotion into a musical piece, ion implantation infuses dopant ions into the wafer, modifying its electrical properties. This step adds the passion and personality needed for the semiconductor device to perform its designated role.

7. Annealing:

The wafer undergoes a high-temperature annealing process to activate dopants and repair any damage caused during ion implantation. This step ensures the proper functioning of the fabricated devices.

Analogy: After the infusion of passion, the semiconductor wafer enters the annealing stage, a high-temperature process that acts as the resonance chamber. Here, the dopants are activated, and any imperfections are ironed out, ensuring the semiconductor’s resonant performance.

Read More: How Much Does a 2 nm Fab Process Cost?

8. Chemical Mechanical Polishing (CMP):

CMP is used to planarize the wafer surface, creating a smooth and even topography. This is crucial for the proper functioning and reliability of the devices.

Anlaogy: Just as a skilled conductor ensures a smooth crescendo, CMP plans the surface of the wafer, creating a harmonious and even topography. This step is crucial for the proper functioning and reliability of the semiconductor devices, smoothing out any rough edges in the musical composition.

9. Metrology and Inspection:

Engineers conduct various measurements and inspections throughout the fabrication process to ensure that each step meets the required specifications. This involves using sophisticated tools to check dimensions, layer thickness, and other parameters.

Analogy: In a symphony, precise tuning is essential for a flawless performance. Similarly, metrology and inspection tools meticulously measure and inspect each aspect of the semiconductor’s composition. This ensures that the devices meet the required specifications, akin to tuning the instruments before a grand performance.

Read More: What is a Fab Lite Model: Advatages and Comparison with Other Models

10. Packaging:

As the grand finale approaches, the semiconductor devices emerge from the wafer, undergo meticulous packaging, testing, and preparation for distribution and use.

Analogy: As the symphony reaches its grand finale, the semiconductor devices are cut from the wafer and carefully packaged. This packaging is the final act, presenting the masterpieces to the world, ready to take their place in the ensemble of modern electronics.

Conclusion:

The semiconductor manufacturing process, much like a symphony, involves a harmonious interplay of elements, each contributing to the creation of the technological melodies that surround us.