Introduction

In the ever-evolving landscape of the semiconductor industry, the infusion of edge computing emerges as a transformative force, tackling challenges and enhancing various facets of semiconductor manufacturing. Let’s embark on an in-depth journey to unravel seven ways edge computing is transform the semiconductor industry.

What is Edge Computing

Edge computing is a distributed computing paradigm that brings data processing closer to the source of data generation, rather than relying on a centralized cloud-based system. Additionally,In traditional cloud computing, data is sent to a centralized cloud server for processing and analysis. However, with edge computing, these operations are performed on local devices or on edge servers situated closer to the data source.

Edge Computing’s Impact on Semiconductor Manufacturing

In the dynamic realm of semiconductor manufacturing, edge computing emerges as a transformative force. This article explores seven ways in which edge computing revolutionizes precision, automation, and safety, shaping a future of efficiency and innovation in the industry.

Read More: How much Do you know Semiconductor Manufacturing – techovedas

Precision in Miniaturization:

In the relentless pursuit of smaller chipsets for 5G smartphones, the semiconductor industry encounters the complex challenge of ensuring precision in handling and testing minuscule objects.

Edge computing proves to be a game-changer in this context, offering solutions that enhance accuracy and streamline manufacturing processes.

For example, in laser dicing machines, smart machine solutions powered by edge computing provide visual alignment, motion control, and quick positioning, ensuring both efficiency and the high quality of the final product.

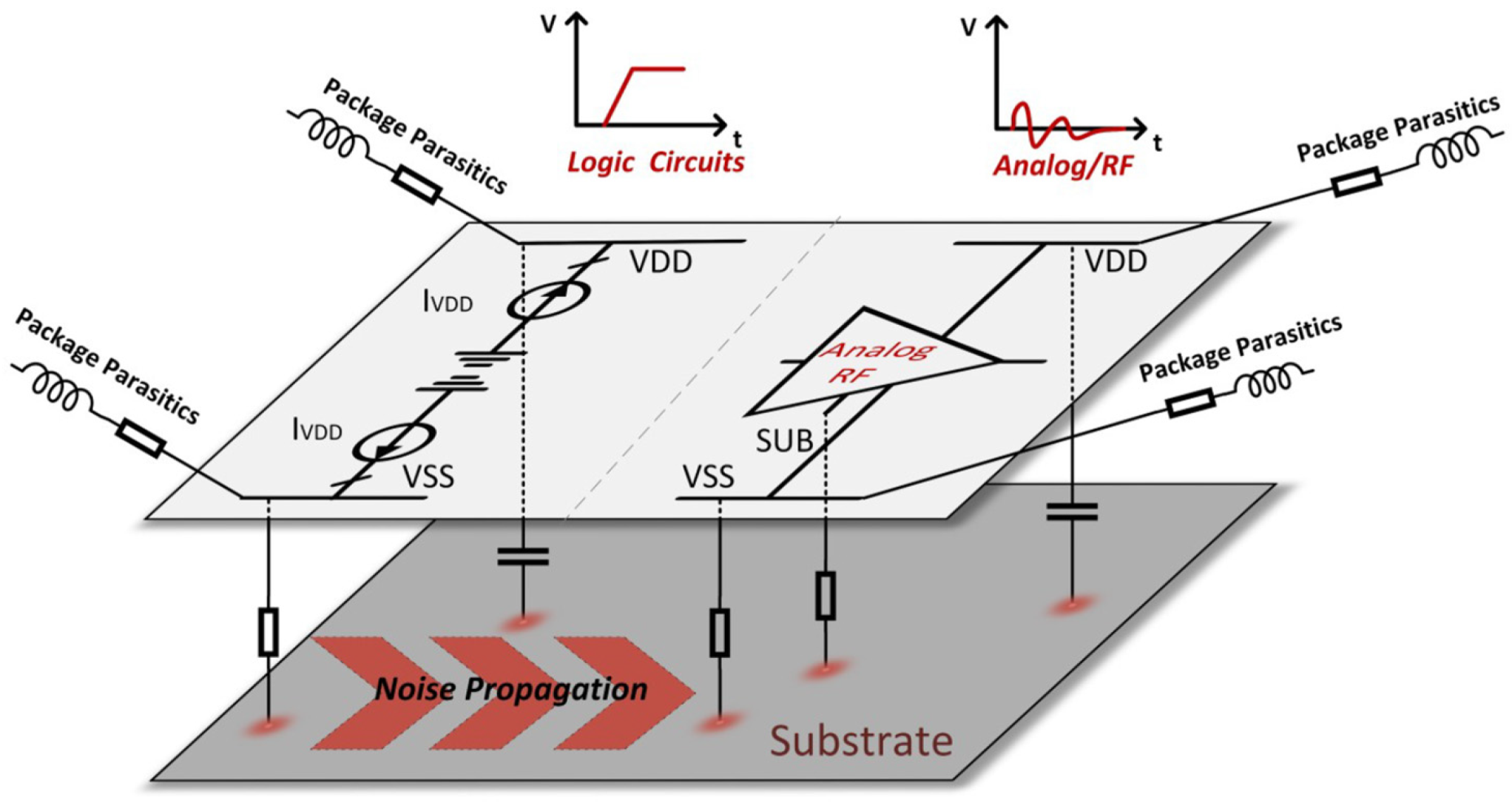

Enhanced Chip-on-Chip Integration:

As the industry embraces 2.5D or 3D manufacturing processes, the integration of chips on chips becomes a complex task, demanding attention to height, length, and width. Additionally, Edge computing steps in as a solution, simplifying the integration of chips on chips.

Additionally, practical terms, semiconductor manufacturing plants can leverage edge computing to optimize chip-on-chip integration processes, addressing current challenges and laying the groundwork for more intricate designs in the future.

Read More: What is a Mixed Signal ICs – Applications and working

Seamless Machine Automation:

The increasing automation in semiconductor manufacturing necessitates real-time data flow to maximize uptime, meet demand, and accommodate frequent machine and program changes.Moreover, Edge computing proves indispensable in ensuring the seamless flow of real-time data to and from machines.

In a hypothetical semiconductor fabrication plant, the integration of edge computing solutions optimizes automation processes, allowing for agile responses to changing production needs, frequent machine reprogramming, and overall automation efficiency.

Read More: Top 10 Semiconductor Equipment Companies of 2023 – techovedas

Predictive Maintenance Excellence:

Semiconductor manufacturers rely on immediate alerts to equipment abnormalities for predictive maintenance, crucial for avoiding downtime and waste. Intelligent solutions, empowered by edge computing, continuously monitor equipment conditions.

For instance, in monitoring the health of dry pumps in semiconductor manufacturing, edge computing ensures real-time data availability, preventing unexpected failures and minimizing waste.

Automated Employee Safety Protocols:

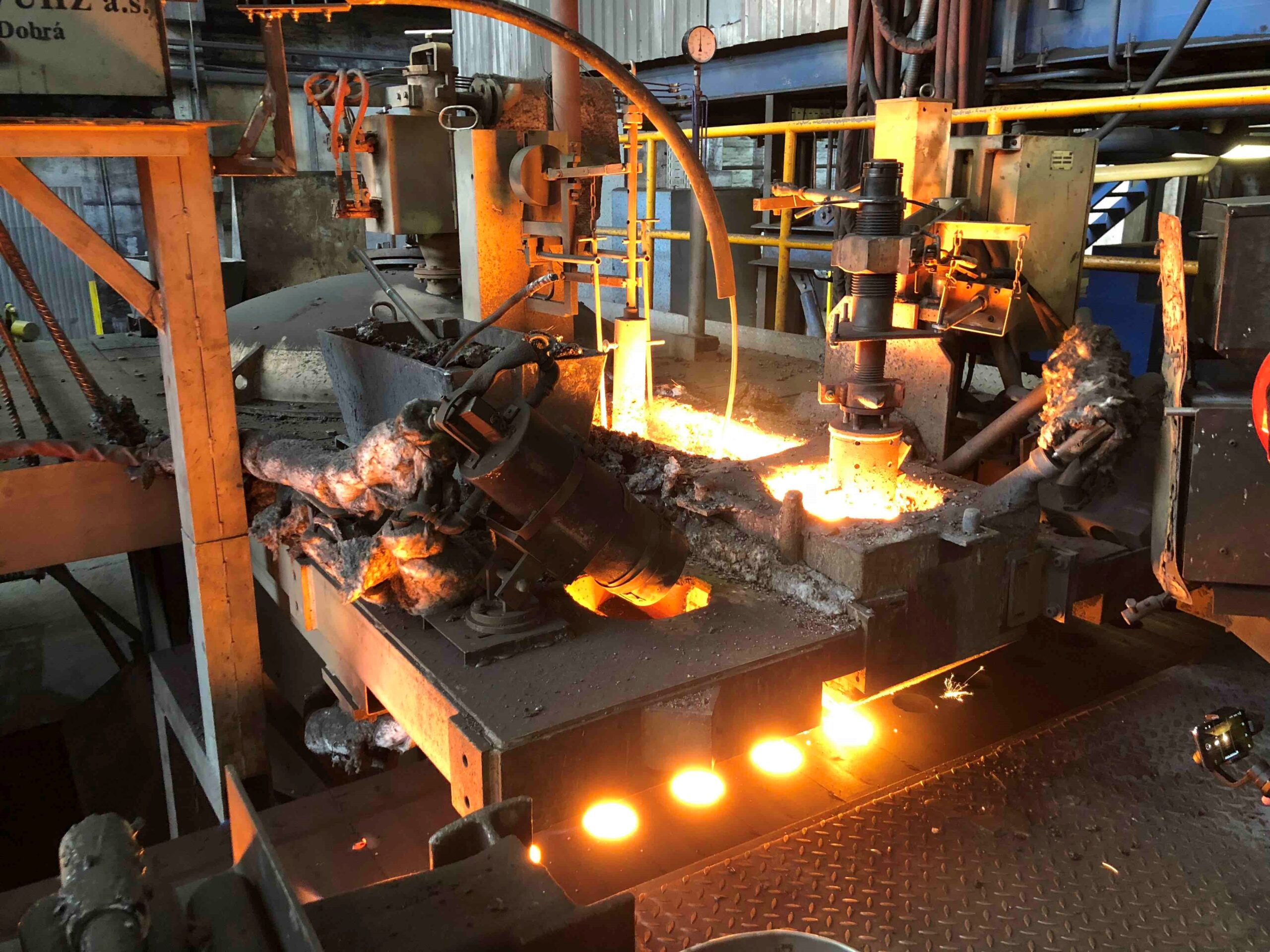

Employee safety is paramount in semiconductor manufacturing, requiring strict adherence to safety procedures and personal protective equipment. Furthermore, the integration of edge computing, robotics, and automation provides a solution for automating hazardous tasks.

In practice, this could involve automating hazardous chemical offloading processes using robotics and edge computing solutions to enhance employee safety by reducing proximity to potentially dangerous processes.

Read More: 12 High-Profit Semiconductor Stocks to Watch in 2024 – techovedas

High-Precision Automation in Die Sorting:

Sorting good dies from flawed ones is a critical step in semiconductor manufacturing, facing bottlenecks due to inadequate speed and accuracy. Additionally, Smart machine solutions, driven by edge computing, introduce rapid feedback and precision necessary to improve throughput in die sorting processes.

In a semiconductor manufacturing facility, edge computing in die sorting machines enhances the efficiency and reliability of the sorting process, directly impacting the quality of the final product.

AI-Enabled Worker Safety and SOP Compliance:

Semiconductor manufacturing involves hazardous processes, emphasizing the need for adherence to standard operating procedures (SOP) to ensure worker safety. Additionally,the synergy of edge computing, AI, robotics, and automation addresses this need by automating hazardous processes.

Envisioning a semiconductor plant where AI-enabled robotics consistently comply with standard operating procedures showcases the potential for edge computing to keep pace with the speed of production and ensure consistent adherence to safety protocols.

Conclusion

In conclusion, the infusion of Edge Computing Transform the Semiconductor Industry marks a paradigm shift, addressing challenges and ushering in a new era of efficiency, safety, and innovation. From precision in manufacturing to the automation of hazardous tasks, each application of edge computing serves as a testament to its transformative power within the semiconductor landscape.

Additionally, As the industry continues to evolve, the collaboration between human ingenuity and cutting-edge technology, embodied by edge computing, promises a future where semiconductor manufacturing is not only efficient but also sustainable and safe.