Introduction

Semiconductor packaging is the unsung hero of the tech world, playing a crucial role in the functionality and performance of electronic devices.

While the average consumer may not give it much thought, semiconductor packaging is a behind-the-scenes marvel that ensures the proper functioning and durability of the electronic components we rely on daily.

Join Our WhatsApp News for updated information on semiconductors & AI

Understanding Semiconductors

Before delving into semiconductor packaging, let’s first grasp the concept of semiconductors. Semiconductors are materials with electrical conductivity between that of a conductor and an insulator.

They form the backbone of electronic devices, facilitating the flow of electrical current. Silicon is the most common semiconductor material, owing to its excellent electrical properties.

Read More: CV Raman: First Indian to Win a Nobel Prize in Science

The Need for Packaging

Semiconductors need packaging for several crucial reasons that are essential to their functionality, reliability, and integration into electronic devices.

Let’s explore these reasons in more detail:

Protection from Environmental Factors:

Semiconductors are highly sensitive to environmental conditions such as moisture, dust, and contaminants. Exposure to these elements can lead to corrosion, short circuits, or other forms of damage. Packaging provides a protective enclosure, shielding the semiconductor from external factors and ensuring its longevity and reliability.

Mechanical Protection:

Semiconductor materials, often silicon, are inherently brittle. They can be easily damaged by physical stress, shock, or vibration. Packaging serves as a buffer, absorbing mechanical shocks and preventing the semiconductor from cracking or breaking during handling, shipping, or everyday use.

Electrical Connection:

Packaging plays a vital role in integrating semiconductor devices into larger electronic systems by providing a direct means for electrical connection. The packaging incorporates leads, pins, or solder balls, enabling the semiconductor to establish a connection with a printed circuit board (PCB) or other components within the system.

Heat Dissipation:

During operation, semiconductor devices generate heat. Efficient heat dissipation is crucial to prevent overheating, which can degrade performance and, in extreme cases, lead to the failure of the semiconductor. Designers incorporate features like thermal pads, heat sinks, or other cooling mechanisms into packaging to dissipate heat and maintain optimal operating temperatures.

Size Reduction and Miniaturization:

Packaging technologies contribute to the ongoing trend of size reduction and miniaturization in electronic devices. Smaller packages enable the creation of more compact and lightweight products. This holds particular significance in applications with limited space, such as in mobile devices, wearables, and IoT (Internet of Things) devices.

Enhanced Electrical Performance:

Packaging can play a role in improving the electrical performance of the semiconductor device. For example, advanced packaging techniques like Ball Grid Array (BGA) or Wafer Level Packaging (WLP) provide more efficient electrical connections, reducing parasitic effects and enhancing signal integrity.

Facilitation of Testing and Quality Control:

Packaging allows for easier testing and quality control of semiconductor devices. Once packaged, rigorous testing procedures ensure that devices meet required specifications and standards before integrating them into electronic systems.

In summary, semiconductor packaging is not just a protective shell; it is a critical element that ensures the semiconductor’s functionality, reliability, and seamless integration into the complex world of electronic devices. Without packaging, the sensitive semiconductor materials would be susceptible to damage and environmental influences, hindering their performance and overall utility in modern technology.

Read More: Simon Sze, Inventor of Floating Gate MOSFET, Passes Away

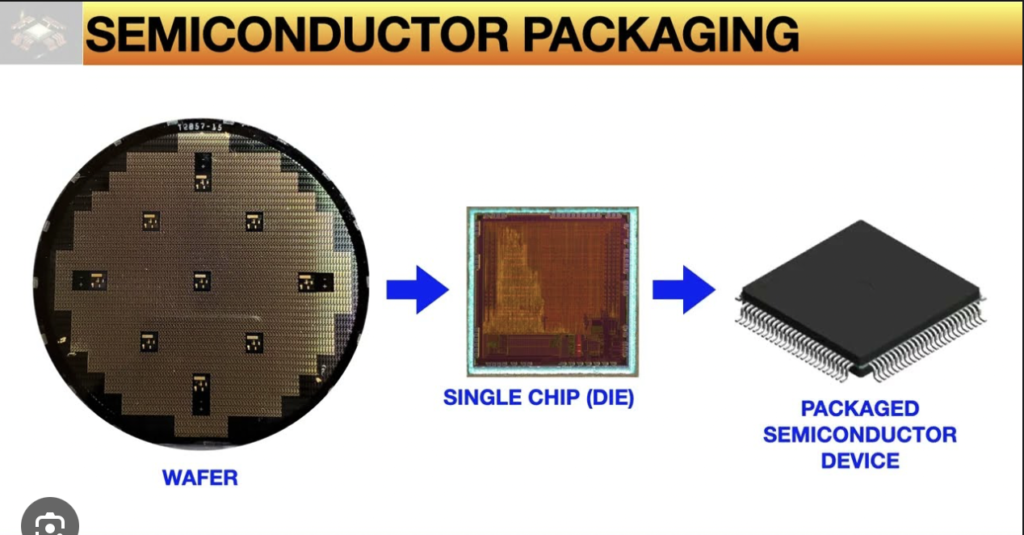

The Basics of Semiconductor Packaging

Semiconductor packaging is the process of enclosing a semiconductor device in a protective case that shields it from external elements. This packaging serves several crucial functions, including:

Protection: It guards the semiconductor against physical damage, moisture, and contaminants.

Electrical Connection: The packaging provides a means to connect the semiconductor device to the larger electronic system, typically through leads or solder balls.

Heat Dissipation: Semiconductor devices generate heat during operation, and effective packaging ensures efficient heat dissipation to prevent overheating and potential damage.

Size Reduction: Packaging often involves miniaturization, allowing for smaller and more compact electronic devices.

Read More: JC Bose: Why was the ‘Father of Radio Science’ forgotten By Western World?

Types of Semiconductor Packaging

Let’s delve into each of these common semiconductor packaging types to understand their characteristics and applications:

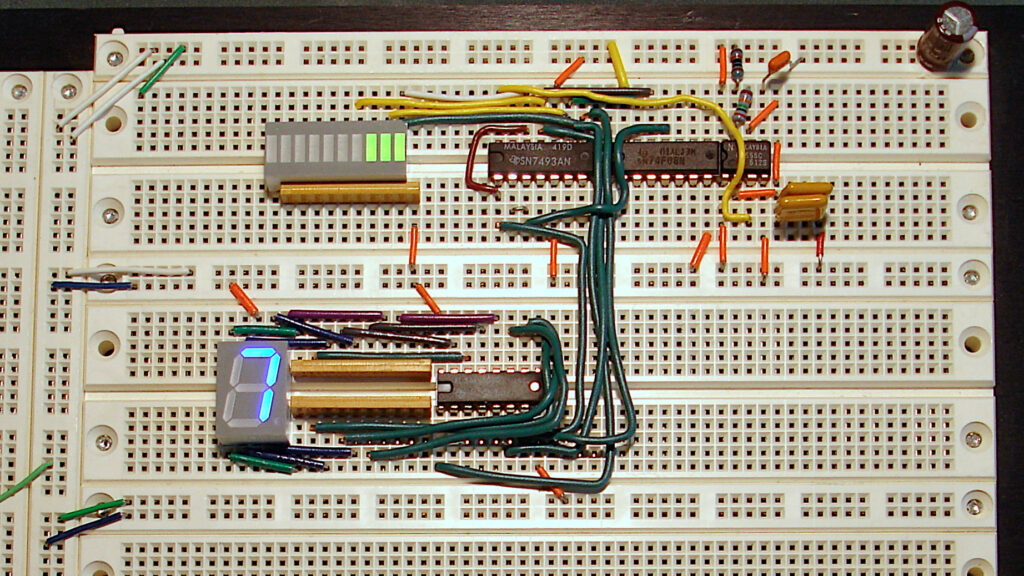

Dual In-Line Package (DIP):

Description: DIP is a traditional packaging format characterized by two parallel rows of pins extending from the sides of the package. The pins are inserted into holes on the printed circuit board (PCB) for electrical connection.

Applications: DIP packages are commonly used in through-hole mounting applications, where components are mounted by inserting their leads through holes in the PCB and then soldering them in place. They are often found in older electronic devices and in applications where robust and reliable connections are crucial.

An operating prototyped circuit on a solderless breadboard incorporating four DIP ICs, a DIP LED bargraph display (upper left), and a DIP 7-segment LED display

Surface Mount Device (SMD):

Description: SMD is a compact packaging type designed for direct mounting onto the surface of a PCB. Instead of leads, SMD components have small metal contacts or solder joints on the bottom surface.

Applications: SMD packaging is prevalent in modern electronics due to its space-saving design. It allows for automated assembly processes, making it suitable for high-volume manufacturing. SMD components are commonly used in consumer electronics, telecommunications, and automotive applications.

The capacitors and resistors pictured are 0603 (1608 metric) package sizes, along with a very slightly larger 0805 (2012 metric) ferrite bead.

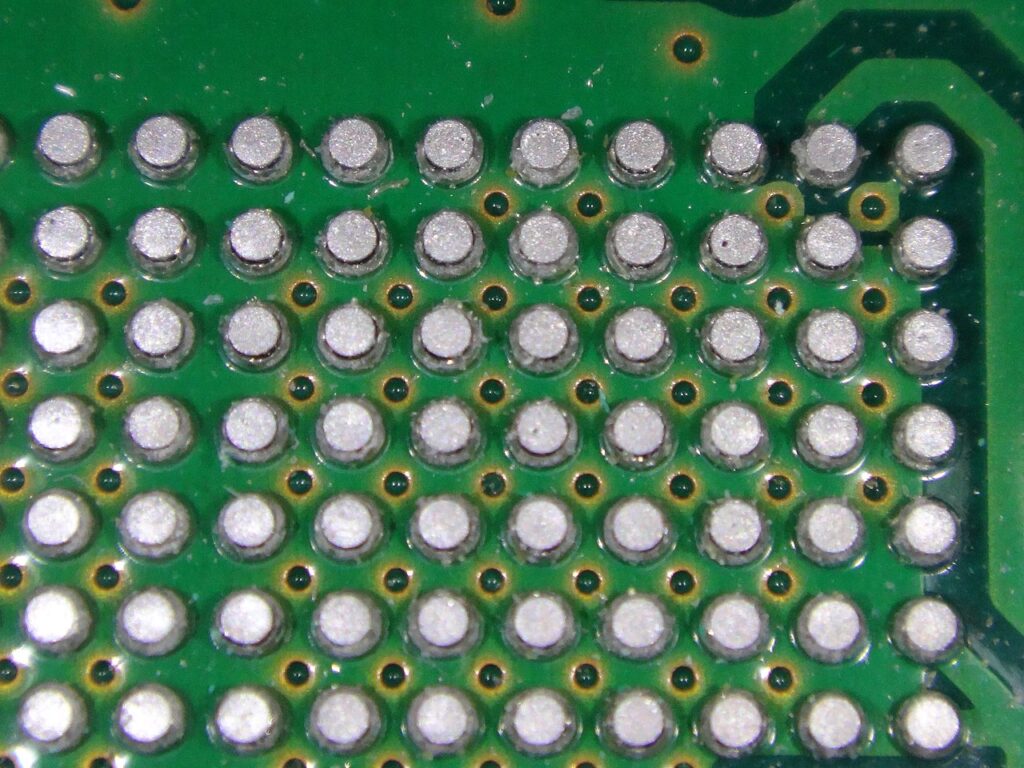

Ball Grid Array (BGA):

Description: BGA is a packaging type featuring an array of solder balls on the underside of the package. These solder balls provide both electrical connections and enhance heat dissipation.

Applications: BGAs are widely used in applications where space is at a premium and efficient heat dissipation is crucial. They are common in microprocessors, GPUs (Graphics Processing Units), and other high-performance integrated circuits. BGAs are also suitable for applications requiring reliable connections in environments with mechanical stress.

Ball grid array of solder drops under an integrated circuit (IC chip removed, the balls are attached to the printed circuit board).

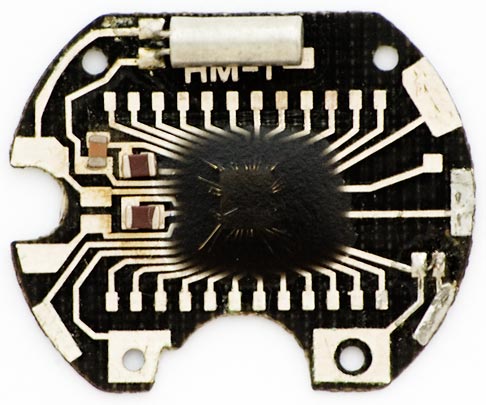

Chip-on-Board (COB):

Description: COB involves directly mounting the semiconductor die (the actual silicon chip) onto the PCB without a traditional package. The die is typically attached using adhesives or solder.

Applications: COB is often employed in applications where size and weight constraints are critical. It is commonly used in LED (Light Emitting Diode) displays, sensors, and other applications where miniaturization is essential. COB can offer cost savings and improved thermal performance.

The PCB of a quartz watch. The clock IC is under the drop of black epoxy.

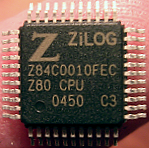

Quad Flat Package (QFP):

Description: QFP is a packaging type characterized by a square or rectangular package with leads extending from all four sides. The leads are usually arranged in a grid pattern.

Applications: QFPs are versatile and find applications in a wide range of electronic devices, including microcontrollers, memory chips, and other integrated circuits. They offer a good balance between size, ease of manufacturing, and electrical performance.

Understanding these semiconductor packaging types provides insights into the diverse methods used to house and connect semiconductor devices. Each type has its advantages and is chosen based on specific application requirements, manufacturing processes, and performance considerations.

A Zilog Z80 in a 44-pin QFP

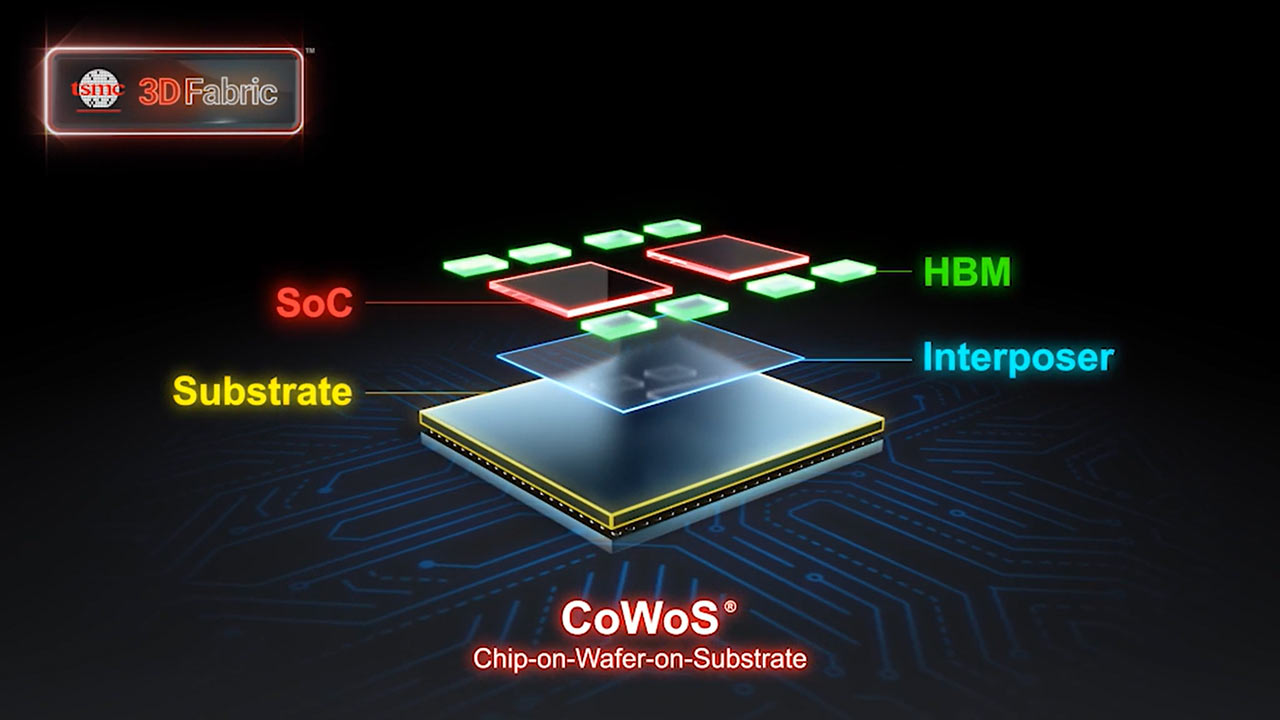

Read More: CoWoS: TSMC’s New Secret Weapon for Advanced Packaging

Difference between Packaging?

| Feature | Dual In-Line Package (DIP) | Surface Mount Device (SMD) | Ball Grid Array (BGA) | Quad Flat Package (QFP) |

|---|---|---|---|---|

| Physical Configuration | Two parallel rows of pins | Compact, with no leads on sides | Array of solder balls | Square or rectangular with leads on all sides |

| Mounting Type | Through-hole mounting | Surface mount onto PCB | Surface mount onto PCB | Surface mount onto PCB |

| Applications | Older electronic devices, through-hole applications | Widely used in modern electronics, automated assembly | High-performance ICs, microprocessors, GPUs | Versatile, used in a variety of applications including microcontrollers, memory chips |

| Space Efficiency | Larger footprint due to through-hole design | Compact, space-saving design | Compact footprint, efficient use of space | Versatile size options, balance between size and ease of manufacturing |

| Heat Dissipation | Limited heat dissipation | Moderate heat dissipation | Efficient heat dissipation | Moderate heat dissipation |

| Common Use Cases | Legacy applications, where through-hole mounting is preferred | Consumer electronics, telecommunications | Microprocessors, high-performance ICs | Microcontrollers, memory chips, various integrated circuits |

| Ease of Manufacturing | Manual assembly for through-hole mounting | Suitable for automated assembly processes | May require advanced manufacturing techniques | Suitable for automated assembly processes |

| Advantages | Robust connections, suitable for certain legacy applications | Space-efficient, suitable for high-volume production | Efficient heat dissipation, compact design | Versatile, balance between size and ease of manufacturing |

| Disadvantages | Larger size, not ideal for miniaturized designs | Limited heat dissipation, manual assembly for some components | Potential complexity in manufacturing, may be costlier | Moderate heat dissipation, not as space-efficient as some other types |

This table provides a concise overview of the differences between DIP, SMD, BGA, and QFP packaging, considering various aspects such as physical configuration, mounting type, applications, heat dissipation, ease of manufacturing, and advantages/disadvantages.

Read More: Explained: What the hell is 3D IC packaging?

Conclusion

In conclusion, semiconductor packaging is the unsung hero that ensures the reliability, durability, and functionality of the electronic devices we rely on daily.

As technology continues to evolve, so too will semiconductor packaging, playing a pivotal role in shaping the future of electronics.

Next time you marvel at the sleek design and powerful performance of your favorite gadget, take a moment to appreciate the intricate world of semiconductor packaging that makes it all possible.

Part 2- What is advanced packaging ?

Part 3- How top Semiconductor Foundries are racing for Packaging.

Stay tuned.