Introduction

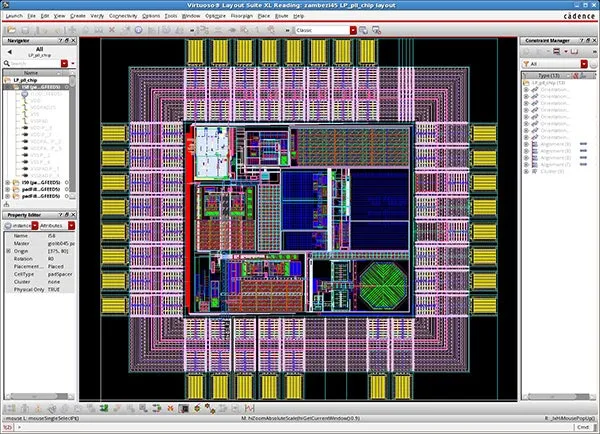

In VLSI design, the layout process is critical to ensuring that a chip meets its performance, power, and area targets. The digital chips follow the physical design flow involving typical steps of floorplan, placement, clock tree synth and routing. These are highly automated. There is another flow for doing the layout right from the scratch. This process can be grouped under the topic custom layout flow. The custom layout flow is further divided into full custom and semi-custom layout design.

This article delves into the nuances of full custom and semi-custom layouts, providing circuit examples, industry use cases, and an overview of relevant open-source tools.

What is Custom Layout?

Custom layout in VLSI design refers to the manual process of designing the physical representation of an integrated circuit at the transistor level. Designers specify the exact placement of transistors, resistors, capacitors, and the interconnections between them. This meticulous process ensures that the circuit performs optimally in terms of speed, power consumption, and area efficiency. Custom layouts are essential for achieving the highest levels of performance and are typically used in high-end applications where every nanometer of silicon real estate counts.

Read more Physical Design Interview Questions – techovedas

Full custom and semi-custom layout flows are two approaches for designing the internal circuitry of an integrated circuit (IC). Here’s a breakdown of each with an example:

Full Custom Layout Flow:

Imagine you’re building a house entirely from scratch. You design every single element, like walls, doors, windows, and even the bricks. This is similar to a full custom layout.

Process:

- Schematic Capture: You define the functionality of the circuit using a schematic diagram, like a blueprint for the house.

- Transistor Layout: You design the layout of each transistor, the fundamental building block of an IC, from scratch. This is like creating the individual bricks for your house.

- Placement & Routing: You carefully position all the transistors and connect them with wires, ensuring optimal performance and minimal wasted space. This is like arranging the bricks and building the walls and pathways in your house.

- Verification & Simulation: You run simulations to check for errors and ensure the circuit functions as intended. This is like checking the structural integrity and functionality of your house before construction.

- Fabrication: Finally, the layout is sent for fabrication on a silicon wafer.

- Pros: Offers ultimate control and customization for high-performance circuits.

- Cons: Very time-consuming, expensive, and requires specialized expertise.

Semi-Custom Layout Flow:

Think of building a house from pre-fabricated modules. You choose pre-designed components like walls, doors, and windows, and then assemble them to create your unique layout.

Process:

- Functional Definition: Similar to full custom, you define the overall functionality of the circuit.

- Cell Library Selection: You choose pre-designed and pre-verified logic cells (like gates, flip-flops) from a library, similar to selecting pre-built modules for your house.

- Placement & Routing: You arrange the chosen cells and connect them with wires using specialized software tools. This is like assembling the pre-built modules and connecting them with electrical wires in your house.

- Verification & Simulation: You run simulations to check for errors in your assembly.

- Fabrication: The layout is sent for fabrication.

- Pros: Faster, less expensive, and requires less expertise compared to full custom.

- Cons: Offers less flexibility and customization compared to full custom.

Example:

Imagine designing a circuit to control the blinking of LEDs.

- In a full custom flow, you’d design the transistors that form the logic gates and the timer circuit. This would be very time-consuming.

- In a semi-custom flow, you’d use pre-designed logic gates and timer cells from a library, then connect them to control the LEDs. This would be faster and less complex.

The choice between full custom and semi-custom depends on factors like project requirements, budget, and time constraints.

Full Custom Layout

Design Strategy

Full custom layout is the most granular approach to chip design. It involves the manual placement and routing of every individual transistor and interconnect. This method provides the highest level of customization and optimization, allowing designers to achieve exceptional performance metrics.

In a full custom layout, designers create the physical design from scratch, which means they have control over every aspect of the chip’s architecture. This includes the exact positioning of transistors, the width and length of each transistor, and the routing of metal interconnections.

Full-custom layouts are driven by a schematic-based design style versus a language-based design style which uses Verilog or VHDL (the basis for the ASIC design flow)

Use Cases

In digital CMOS VLSI, full-custom design is rarely used due to the high labour cost. Full custom layouts are predominantly used in applications where performance is paramount. Some common examples include:

- Analog and Mixed-Signal Circuits: Circuits such as PLLs (Phase locked loops), ADCs (Analog-to-Digital Converters) and DACs (Digital-to-Analog Converters), where precise control over the layout can significantly impact performance.

- RF Circuits: Radio Frequency circuits where the layout affects signal integrity and overall performance.

Read more A day in the life of Physical Design engineer – techovedas

Circuit Example

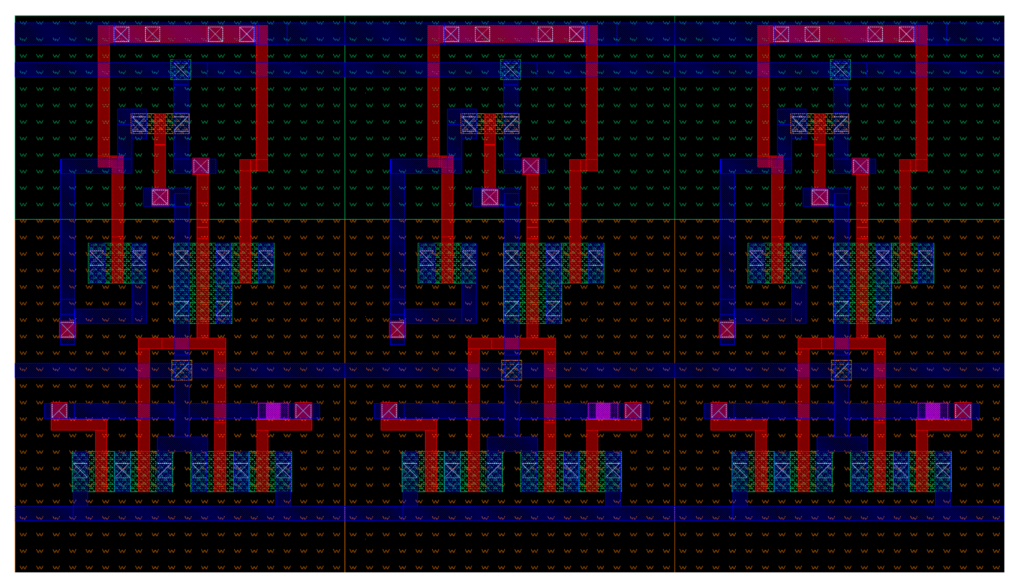

The most intricate example of a full custom layout is Memory layout design. Memory layout design first depends on the layout of the memory cell. As the memory cell is repeated, cell efficiency is paramount. Therefore, a team of design engineers, layout designers, and processing specialists will invest months to develop the smallest size cell with the performance required for the application.

Surrounding these memory cells, a lot of effort is expended to build all of the interface circuitry. These blocks have to match the pitch of the memory cell and provide the functionality that, in this case, is much more complicated.

The pitch of a memory cell refers to the distance between two successive memory cells in a memory module or array. For such a design style, a flow that allows architecture exploration and fast back annotation to design is a must.

Read more What are the 5 Steps involved in Physical Design of VLSI Chips – techovedas

Open-Source Tools for Full Custom Layout

Several open-source tools support full custom layout design. Some of the notable ones include:

- Magic VLSI: An open-source layout tool widely used in academia and industry for its ease of use and powerful features for full custom design.

- KLayout: Another open-source layout editor and viewer that provides advanced features for full custom design and verification.

Read more Top EDA Tools in Each Step of ASIC Design Flow – techovedas

Semi-Custom Layout

Design Strategy

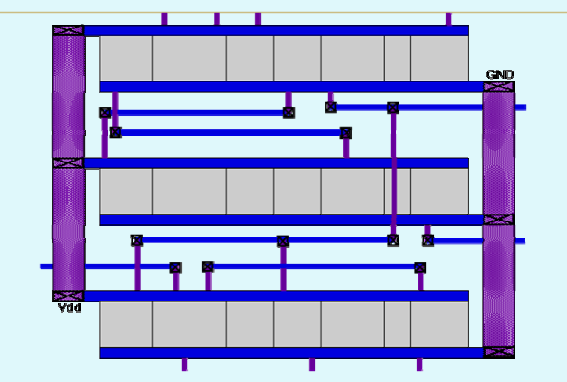

Semi-custom layout or Standard cell layout offers a middle ground between full custom design and automated design flows. In this approach, designers use pre-designed standard cells from a cell library. These standard cells are pre-characterized for performance, power, and area, which speeds up the design process.

A typical library may contain a few hundred cells, e.g., inverters, NAND gates, NOR gates, D-latches, and flip-flops.

The semi-custom approach involves placing and routing these standard cells to create the desired circuit. While it limits the degree of customization compared to full custom design, it significantly reduces design time and effort.

Read more Explained: What is Standard Cell in VLSI Design – techovedas

Use Cases

Semi-custom layouts are ideal for applications where a balance between performance and design time is required. Some typical examples include:

- Application-Specific Integrated Circuits (ASICs): Custom chips designed for specific applications where time-to-market and cost are critical.

- General Digital Circuits: Circuits such as controllers, communication interfaces, and other non-critical digital logic.

Circuit Example

Consider a digital signal processing (DSP) block within an ASIC. Using a semi-custom layout, the designer would utilize standard cells like logic gates, flip-flops, and multiplexers from a pre-defined library. These cells are placed and routed to form the DSP block, ensuring a good balance between performance and design efficiency.

Open-Source Tools for Semi-Custom Layout

Several open-source tools are available for semi-custom layout design:

- OpenROAD: An integrated tool for the physical design of digital circuits, supporting semi-custom design flows.

- Yosys: A framework for RTL synthesis that works well with other open-source tools for semi-custom design.

- Magic VLSI: An open-source layout tool widely used in academia and industry. It comes it use in both semi-custom and full custom layout design.

Conclusion

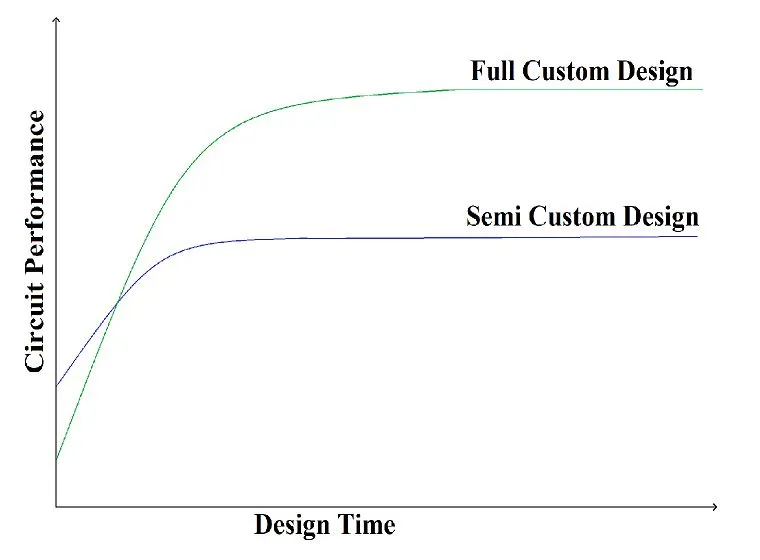

From the above graph we can conclude following points:

- Initial circuit performance of the full custom design is less as compared to semi-custom design as we design it from the basic transistor level.

- Semi-custom has designed less time compared to full custom design to get a stable circuit performance.

- Circuit performance of the full custom design is higher than the semi-custom design.

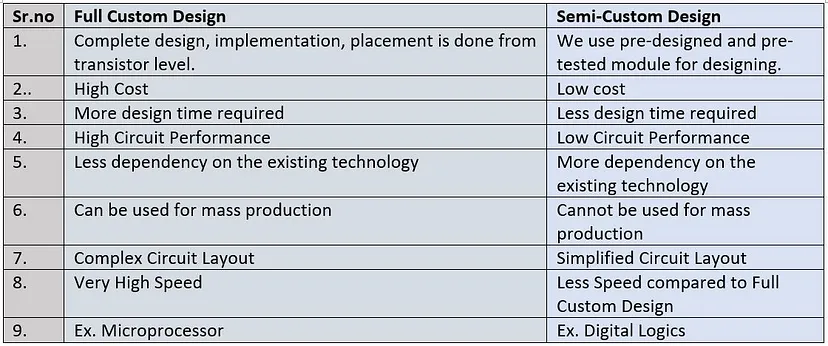

Comparison between Full Custom and Semi-Custom design

In conclusion, both full custom and semi-custom design methodologies are vital in VLSI design. Full custom design delivers exceptional optimization and performance, whereas semi-custom design offers flexibility and quicker time-to-market, especially for smaller-scale projects. Recognizing the advantages and limitations of each approach is critical for choosing the most appropriate methodology according to the project’s needs and constraints.