Introduction

The world is undergoing a significant transformation in how we generate and consume energy. With the rise of electric vehicles and renewable energy sources like solar and wind power, the demand for power electronics packaging has skyrocketed.

But what many people don’t realize is that alongside the development of these high-tech devices, There’s a silent revolution happening in their packaging.

Here are five big shifts driving this change:

Follow us on LinkedIn for everything around Semiconductors & AI

Handling Higher Power Densities:

Imagine cramming more power into smaller devices. That’s exactly what’s happening as we strive for more efficient power supplies and faster conversion rates.

To make this possible, we need packaging materials and techniques that can handle the heat and stress that come with higher power densities. It’s like upgrading from a tiny hatchback to a powerful sports car—you need a stronger chassis to handle the extra horsepower.

Read more: Bankruptcy to Trillion-Dollar Company: Story of Nvidia

Embracing SiC and GaN:

Traditionally, power devices were made using silicon. But now we’re seeing a shift towards wide bandgap materials like silicon carbide (SiC) and gallium nitride (GaN).

These materials are like the superheroes of the semiconductor world—they can switch faster and operate at higher temperatures. It is making them perfect for modern power electronics.

It’s like trading in your old flip phone for the latest smartphone—faster, sleeker, and more efficient.

Read More: First Generative AI Teacher “Iris” Introduced by Kerala; Powered by Intel Processor – techovedas

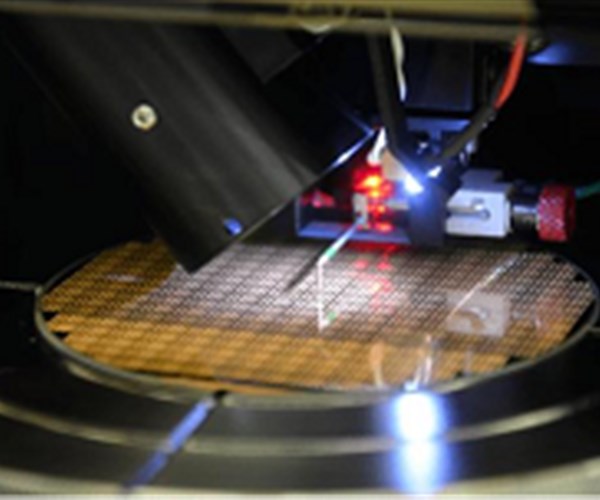

Tackling Packaging Challenges:

With the adoption of SiC and GaN comes a new set of challenges. These materials demand better thermal management, electrical connections, and mechanical stability.

Think of it like upgrading from a basic toolbox to a high-tech workshop—you need the right tools and techniques to handle the job.

That’s where innovations like direct bond copper and embedded substrate approaches come in, providing better heat dissipation and reducing electrical resistance.

Exploring Diverse Package Types:

Power electronics packaging comes in all shapes and sizes, each suited to different applications.

From discrete packages like TO-247 and TO-220 for specific power needs to surface-mount devices. It is like D2PAK and PQFN for space-constrained designs, there’s a packaging solution for every situation.

It’s like choosing the right outfit for the occasion—sometimes you need something formal, sometimes casual, but it always has to fit just right.

Read More: US Urges Japan and Netherlands to Tighten Restrictions on China’s Semiconductor Access – techovedas

Anticipating Future Trends:

As technology continues to evolve, so too will power electronics packaging. Leadless packages and advanced materials like power CSPs are gaining popularity for their space-saving benefits.

Co-design and optimization will become increasingly important, ensuring that packaging and device design work seamlessly together.

It’s like planning for the future—you need to stay ahead of the curve to remain competitive in the fast-paced world of technology.

Read More:Why TSMC Wants OSAT partners to Expand Advanced Packaging ? – techovedas

Conclusion:

The world of power electronics packaging may not be as glamorous as the latest electric car or solar panel, but it’s just as important.

By embracing new materials, innovative techniques, and a collaborative approach to design. We’re paving the way for a future powered by clean energy and efficient electronics.

As demand continues to grow, the evolution of packaging technologies. It will play a crucial role in shaping the future of power electronics.

So next time you plug in your electric car or switch on your solar-powered home, take a moment to appreciate the silent revolution happening behind the scenes in power electronics packaging.