Introduction:

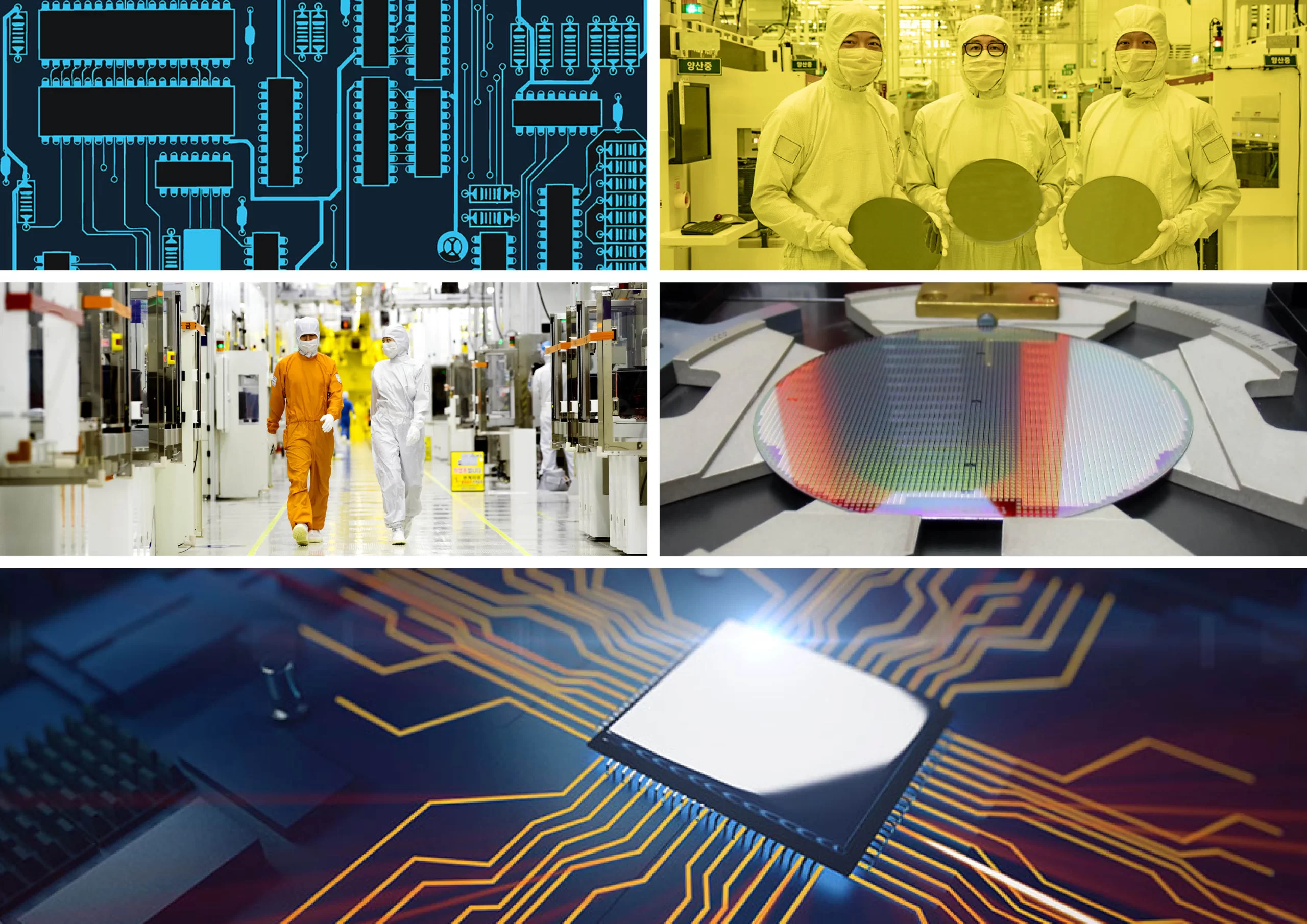

Since the 1960s, semiconductor fabs have played a pivotal role in shaping the modern technological landscape. From their modest origins to the construction of multi-billion-dollar facilities, semiconductor manufacturing has undergone significant evolution and growth. In this blog post, we will embark on a journey through time, exploring the key milestones, technological innovations, and industry trends that have defined the trajectory of semiconductor fabs from 1960 to 2024.

Follow us on LinkedIn for everything around Semiconductors & AI

1960s-1970s: The Birth of Semiconductor Fabs:

The 1960s marked the dawn of semiconductor fabs as pioneering companies like Fairchild Semiconductor and Texas Instruments established the groundwork for modern chip manufacturing.

The 1960s marked the dawn of semiconductor fabs as pioneering companies like Fairchild Semiconductor and Texas Instruments established the groundwork for modern chip manufacturing.

These early fabs were relatively small-scale facilities equipped with basic semiconductor fabrication equipment, such as diffusion furnaces and photolithography machines.

Cleanroom technology emerged during this period, allowing for the creation of dust-free environments essential for producing reliable semiconductor devices.

Semiconductor fabs primarily produced simple integrated circuits (ICs) for applications such as calculators, early computers, and military electronics.

Read More:U.S Revokes Licenses to Export Goods, Including Chips to Huawei After AI Laptop Launch – techovedas

1980s-1990s: The Rise of Semiconductor Giants:

The 1980s and 1990s witnessed the rapid expansion and consolidation of the semiconductor industry, with the emergence of dominant players like Intel, IBM, and TSMC. Fueled by advancements in silicon processing technology and increasing demand for microprocessors and memory chips, semiconductor fabs underwent a transformational period of growth and innovation.

Companies invested heavily in the construction of larger and more advanced fabs equipped with cutting-edge manufacturing equipment.

Additionally, Semiconductor fabs embraced silicon wafers with larger diameters, transitioning from 4-inch to 8-inch and eventually 12-inch wafers to increase chip yields and reduce production costs.

The adoption of deep ultraviolet (DUV) lithography enabled finer feature sizes and higher chip densities, laying the groundwork for the production of increasingly complex semiconductor devices.

Read More: China Bans Intel and AMD From Government Computers

2000s-2010s: The Era of Technological Innovation:

The 2000s and 2010s ushered in an era of unprecedented technological innovation in semiconductor fabrication.

Faced with the challenge of scaling Moore’s Law and meeting the demands of Moore’s Second Law (the increasing cost of building fabs), semiconductor companies embraced novel approaches to chip design and manufacturing.

Fabs transitioned to advanced process nodes, such as 45nm, 32nm, and eventually 7nm, enabling the production of high-performance microprocessors, graphics processing units (GPUs), and system-on-chips (SoCs).

The introduction of FinFET transistors and other three-dimensional (3D) structures revolutionized semiconductor design, enhancing performance and energy efficiency.

Concurrently, the rise of system-level integration and heterogeneous computing architectures drove the adoption of 3D packaging technologies, such as flip-chip and through-silicon vias (TSVs), enabling greater levels of chip density and functionality.

Read More: What is Intel-Huawei Export License Controversy & Why AMD is Bleeding Over this?

2020s: Building $20 Billion Semiconductor Fabs:

As we enter the 2020s, semiconductor fabs have evolved into sprawling, multi-billion-dollar facilities at the forefront of technological innovation.

The construction of a $20 billion fab represents a monumental undertaking, requiring state-of-the-art cleanrooms, advanced lithography tools, and cutting-edge process technologies.

Moreover,leading semiconductor companies, including Samsung, TSMC, and Intel, are investing heavily in next-generation fabs to maintain their competitive edge in the global semiconductor market.

These fabs leverage extreme ultraviolet (EUV) lithography, advanced materials such as high-k metal gate (HKMG) transistors, and novel transistor architectures to achieve unprecedented levels of performance, power efficiency, and chip density.

Moreover, the emergence of heterogeneous integration technologies, such as chiplets and 3D stacking, enables the seamless integration of diverse semiconductor components, further pushing the boundaries of semiconductor manufacturing.

Read More: $20 Million Initiative: How Nvidia & MITRE Supercomputer Will Boost AI for US Govt. – techovedas

Challenges and Opportunities:

While the construction of $20 billion semiconductor fabs presents immense opportunities for innovation and growth, it also poses significant challenges.

Rising construction costs, geopolitical tensions, and supply chain disruptions can impact fab construction timelines and budgets.

Additionally, the complexity of semiconductor manufacturing requires a highly skilled workforce and robust quality control measures to ensure the reliability and yield of fabricated chips.

Semiconductor companies must navigate these challenges while embracing new technologies and business models to capitalize on the opportunities presented by the evolving semiconductor landscape.

Read More; Made in India: Tata Electronics Exports First Batch of Semiconductor Chip – techovedas

Conclusion:

The evolution of semiconductor fabs from humble beginnings to $20 billion giants is a testament to the resilience, innovation, and collaborative spirit of the semiconductor industry.

As we look ahead to the future, semiconductor fabs will continue to serve as the backbone of technological progress, enabling breakthroughs in artificial intelligence, 5G connectivity, and autonomous vehicles.

By embracing new technologies, overcoming challenges, and fostering collaboration across the ecosystem, semiconductor companies can build the next generation of fabs that will shape the future of technology for decades to come.