Introduction

As the semiconductor industry advances, chip packaging emerges as a critical component in enhancing device performance. In an era focused on slim, miniaturized electronics, the demand for advanced chip packaging intensifies.

This article delves into the evolving landscape of chip packaging, exploring its vital role in extending Moore’s Law, managing heat in High-Performance Computing (HPC), and integrating diverse components seamlessly.

What is Chip packaging?

Semiconductor chip packaging is the final phase in the semiconductor device production process.

At this critical juncture, the semiconductor block receives a protective covering, shielding the integrated circuit (IC) from potential external hazards and the corrosive effects of time.

This packaging essentially acts as a safeguarding enclosure, shielding the IC block and facilitating the electrical connections responsible for transmitting signals to the circuit board of electronic devices.

Importance of Chip packing

In the context of ever-advancing technology and the relentless drive toward the slimming and miniaturization of electronic devices, demand for semiconductor packages has intensified.

New generation packaging is expected to provide increased density, multi-layer capabilities, and a low-profile design to meet the demands of high-speed, highly integrated, and low-power consumption ICs.

1. Extending Moore’s Law

As computer chips have continued to shrink over the years, more research is required to continue packaging them up as efficiently as possible.

Moore’s Law, the observation that the number of transistors on a chip double roughly every two years, has been the driving force behind the exponential growth of computing power. However, as we approach the physical limits of miniaturization, Moore’s Law is slowing down. This presents a challenge for the electronics industry: how do we continue to improve chip performance when simply shrinking transistors is no longer an option?

This is where chip packaging steps up as a crucial player. Here’s how packaging will play a vital role in overcoming the limitations of Moore’s Law:

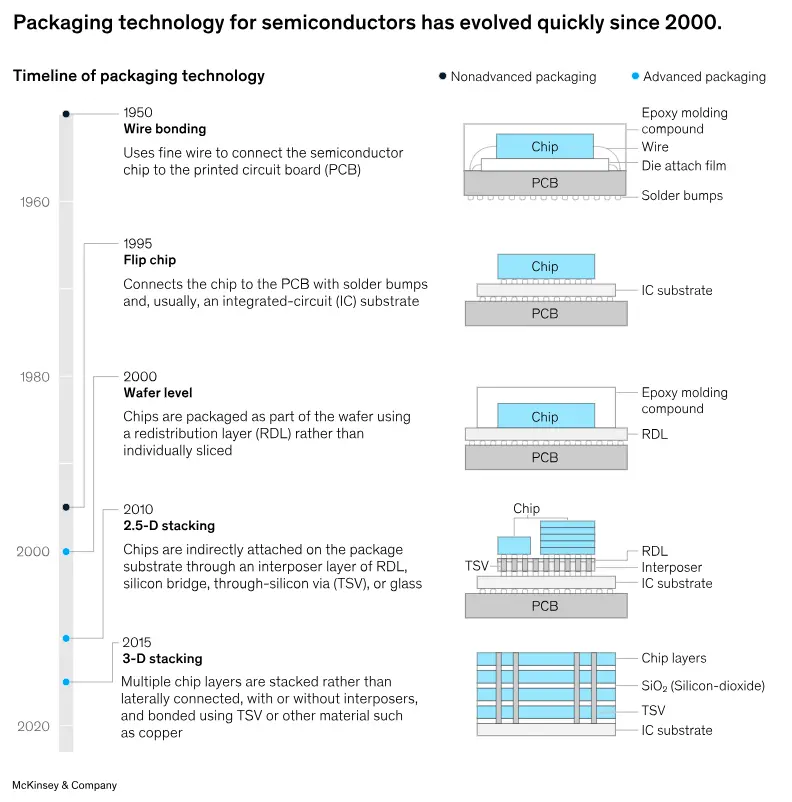

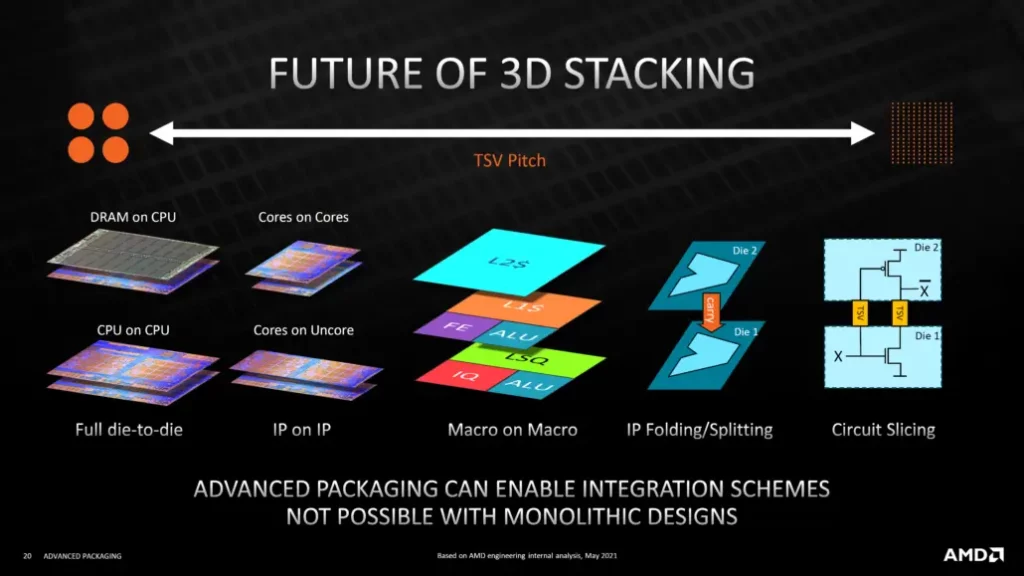

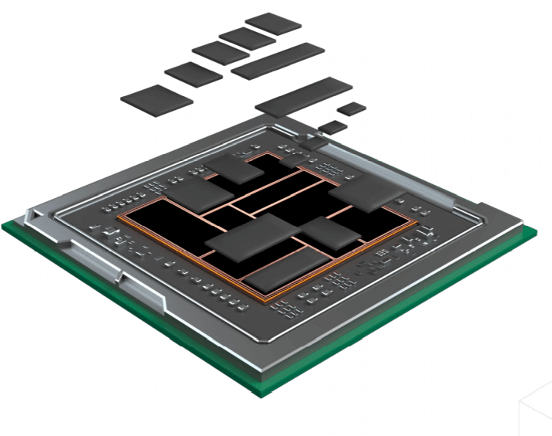

a) 3D Integration: As Moore’s Law slows down, the industry is looking towards 3D integration as a way to continue boosting performance. This involves stacking multiple chips vertically in a single package, allowing for functionalities beyond what a single, miniaturized chip can achieve. Advanced packaging techniques, like Through-Silicon Vias (TSVs) that create vertical connections between chips, are crucial for enabling effective 3D integration.

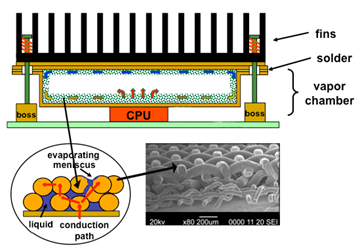

b) Heat Dissipation: Shrinking transistors leads to increased density, which in turn results in more heat generation. Traditional packaging methods struggle to handle this heat effectively.

Moreover, Advanced packaging solutions, like those utilizing heat pipes or vapor chambers, will be essential to efficiently dissipate heat and prevent chip malfunctions.

c) Power Delivery: Delivering sufficient power to the ever-denser circuits within a chip becomes increasingly challenging as miniaturization progresses. Innovative packaging with improved power delivery networks will be necessary to ensure chips receive the power they need to function properly.

Read more What is Backside Power Delivery: Intel’s Secret weapon for Foundry Leadership – techovedas

2. Role of Chip packaging in HPC

In High-Performance Computing, for example, processors require large amounts of close-by memory with short interconnections and high data transfer rates. This near-memory computing requirement is fulfilled by advanced packaging, like Intel’s embedded interconnect bridge and Foveros.

Moreover, Nvidia’s H100 is a commercialized example of advanced packaging, which builds on TSMC’s CoWoS technology. Another example is AMD’s MI300, which uses TSMC’s CoWoS and system on integrated chips (SoIC). AMD’s CEO Lisa Su even stated that AMD “couldn’t have done [MI300] without TSMC”.

Most of the growth in HPC and network applications is likely to come from AI chips, edge computing, and network chips in consumer devices, which require the small form factor and affordable cost.

The most likely driver of growth in 2.5-D stacking could be HPC applications, which are in high demand for data centers. Although less than 20 percent of data-center capacity used 2.5-D stacking in 2022, the rate could increase to 50 percent in the next five years. For mobile applications, 2.5-D packaging is considered too costly, but this may change with the arrival of the next generation, which will feature less expensive silicon bridges, RDLs, and glass interposers.

Read more How Advanced Packaging and Photonics Enable High Performance Computing – techovedas

3. High Bandwidth memory and chip packaging

For 3-D packaging, memory—the dominant application for 3-D stacking—and SoC use are expected to grow at a CAGR of roughly 30 percent.

Additionally, increasingly, 3-D stacked memory is being incorporated with logic chips for high-performance products that require high bandwidth, including high-bandwidth memory (HBM) and processing in memory with HBM (PIM-HBM).

Substantial demand for 3-D stacked memory will likely come from data-center servers, which require high capacity and high speed, and graphics accelerators and network devices, which require the maximum possible bandwidth for memory and processing.

Thermal management in 3D IC

It is a critical aspect of 3D packaging. Moreover, thermal vias are drilled through the package substrate or interposer layer to facilitate heat transfer between the stacked chips and the cooling system.

By connecting the heat-generating components to the heat dissipation mechanisms, thermal vias help distribute heat evenly throughout the package and improve overall thermal performance.

Read More: Qualcomm Unveils Snapdragon 8s Gen 3: A More Affordable Take on flagship processors – techovedas

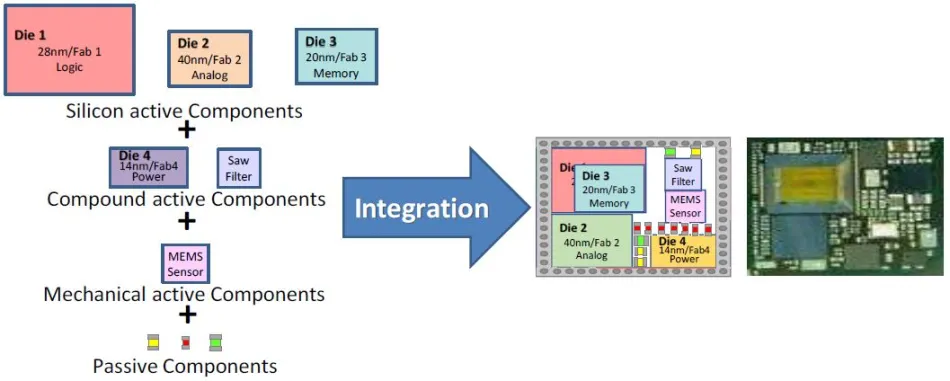

4. Importance of packaging in heterogenous integration

For many years chip makers used traditional IC scaling to move from one node to the next, but the benefits are shrinking and the costs are escalating. Another way to get the benefits of scaling is by moving to more advanced forms of heterogeneous integration.

By heterogeneous integration, we refer to the concept of putting multiple and different chips in the same package.

Packaging plays a critical role in heterogeneous integration, facilitating the amalgamation of diverse components like chips, sensors, such as memory into a compact form. It enables miniaturization, ensuring efficient utilization of space in modern electronic devices.

Read more What is Heterogeneous integration: Advantages Types and Technology – techovedas

5. Chiplet technology and packaging

Additionally, packaging ensures robust electrical connections between chiplets, minimizing signal loss and managing heat dissipation to maintain optimal performance.

Through careful design, packaging preserves signal integrity and facilitates high-speed communication between chiplets, crucial for efficient data transfer.

Mechanically, packaging provides stability, preventing chiplets from shifting or dislodging, especially in challenging environments.

From a manufacturing perspective, advanced packaging techniques enhance cost-effectiveness and yield rates by enabling separate testing and assembly of individual chiplets.

Moreover, packaging fosters collaborative design efforts, aligning electrical, thermal, and mechanical considerations for optimal system performance.

In essence, packaging serves as a vital bridge, unifying disparate chiplets and ensuring their cohesive functionality in heterogeneous integrated systems.

Read More: Intel’s CHIPS Act Feast: $8.5 Billion Direct Funding + $11 Billion in Loans – techovedas

Conclusion

In essence, chip packaging becomes an extension of the chip itself. As we push the boundaries of miniaturization and performance, chip packaging emerges as a linchpin in ensuring the reliability, efficiency, and functionality of semiconductor devices.

It plays a crucial role in extending Moore’s Law, managing heat in HPC, and integrating diverse components seamlessly.

With the advent of advanced applications such as artificial intelligence, edge computing, and high-performance computing, the demand for smaller, more powerful electronic devices will soar and in all this chip packaging will be play a crucial role.