Introduction

TSMC is one of the world’s leading semiconductor manufacturers, and their recent endeavors in the expansion of their global manufacturing footprint have been making headlines.

During the 3Q23 Earning Call held on October 19th, 2023, TSMC provided updates on its Global Expansion, shedding light on their ambitious plans to establish semiconductor fabrication facilities in various locations across the world.

This blog post will provide a detailed overview of TSMC Global expansion strategy and the latest developments.

TSMC Global Expansion Strategy

TSMC’s global expansion strategy aims to establish semiconductor fabrication plants in key regions to meet the increasing demand for advanced semiconductor technology worldwide.

This strategy involves creating a diversified network of facilities to serve various industries and regions. TSMC’s recent updates reveal their progress and plans for facilities in the United States, Germany, and Japan.

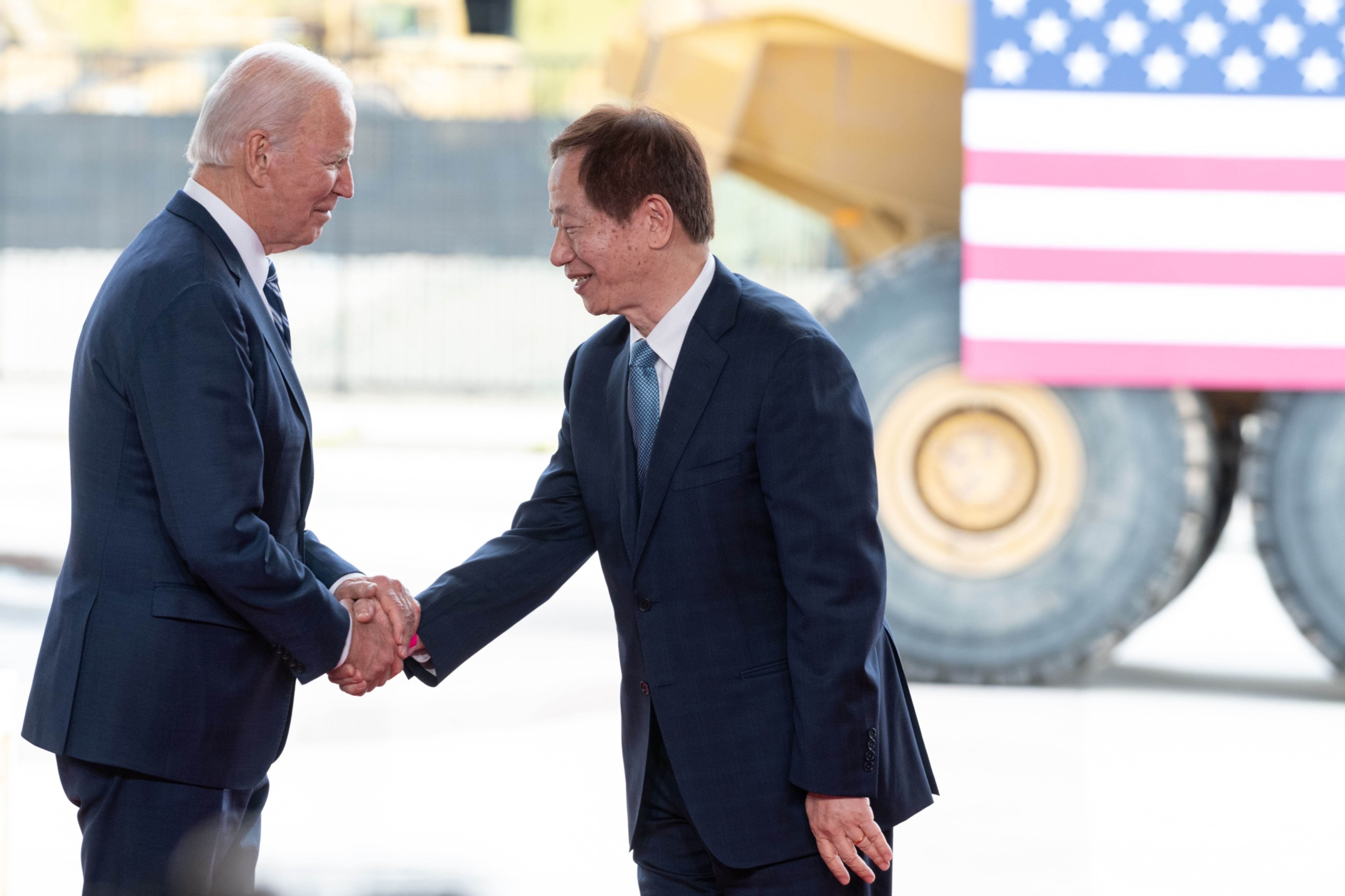

Read More: 5 Reasons TSMC is World’s Leading Chipmaker, as Per Founder Chang

TSMC Global Expansion Challenges

TSMC acknowledged that the initial production costs at overseas plants are higher compared to their Taiwanese facilities.

These higher costs are primarily attributed to the smaller scale of overseas semiconductor fabrication plants and the overall supply chain costs. Overseas semiconductor ecosystems are still in their early stages compared to Taiwan’s mature semiconductor industry.

However, TSMC remains committed to its global expansion strategy and is working to optimize operations in these locations.

Read More: Japan to invest $6 billion in TSMC 2nd fab to produce 6-12nm chips

1. Phoenix, Arizona, USA

The new semiconductor fabrication plant in Phoenix, Arizona, USA, is a significant milestone in TSMC’s global expansion efforts. Here are more details about this state-of-the-art facility and the company’s commitment to its success:

Production Timeline: The Phoenix plant is well on its way to becoming operational. TSMC’s commitment to a strict timeline is evident, with production set to commence in the first half of 2025. This timeline reflects the company’s dedication to ensuring that this facility contributes to meeting the growing demand for advanced semiconductor technology in the United States and beyond.

Local Workforce: One notable aspect of TSMC’s approach to the Phoenix facility is its emphasis on hiring and boosting the local workforce. TSMC has already hired nearly 1,100 local employees, which is a testament to the company’s commitment to fostering economic growth and providing employment opportunities in the region. This not only benefits TSMC but also the local community by creating jobs and driving economic development.

Cutting-Edge Technology: The Phoenix plant is poised to be a showcase of TSMC’s dedication to innovation and cutting-edge semiconductor solutions. The facility is expected to utilize 4-nanometer (N4) technology. The N4 technology is a major advancement, enabling smaller and more efficient semiconductors. TSMC’s use of N4 underscores its leadership in semiconductor manufacturing, aiming to deliver advanced solutions for consumer electronics and the automotive industry.

Strategic Location: Phoenix, Arizona, was strategically chosen as the location for this facility. The region’s infrastructure, proximity to key markets, and favorable business environment make it an ideal choice for TSMC’s expansion. It not only strengthens TSMC’s global presence but also enhances the resilience of semiconductor supply chains, particularly in the United States.

Read More: TSMC to Unveil Next-Gen Transistor Using Ultra Thin MoS2 at IEDM 2023

2. Germany

TSMC’s plans for a specialized semiconductor fabrication facility in Germany, designed to serve the automotive and industrial sectors and featuring 22/28-nanometer and 12/16-nanometer technologies, represent a significant development in the company’s global expansion efforts. Here are more details about this strategic initiative:

Specialized Facility for Automotive and Industrial Sectors:

TSMC’s choice to build a in Germany shows its dedication to serving the automotive and industrial sectors.

These sectors rely on high-performance semiconductors, particularly with the integration of advanced technologies like autonomous driving and smart manufacturing.

Advanced Process Technologies:

The facility in Germany is planned to employ a range of advanced process technologies, including 22/28-nanometer and 12/16-nanometer nodes.

These technologies are well-suited for producing semiconductors that strike a balance between performance, power efficiency, and cost-effectiveness.

By offering these technology nodes, TSMC aims to cater to the diverse needs of the automotive and industrial sectors.

Construction Timeline:

Construction of the semiconductor fabrication facility in Germany is scheduled to begin in the latter half of 2024.

This timeline signifies TSMC’s commitment to executing its expansion plans swiftly and efficiently.

The company is evidently determined to contribute to the European semiconductor manufacturing landscape in a timely manner.

Production Commencement:

TSMC’s target for production commencement by the end of 2027 aligns with its long-term vision for the facility.

This timeline permits the development of a strong infrastructure and the training of a skilled workforce to prepare the facility for European market demands.

European Market Focus:

TSMC’s choice of Germany as the location for this specialized facility is strategic.

Germany is strategically located at the center of Europe’s automotive and industrial hubs, ideal for effective market service. Operating near customers and partners allows TSMC to grasp and meet the region’s distinct semiconductor requirements.

Read More: TSMC 2 nm Process has higher interest than 3 nm at Similar Stage: CEO

3. Kumamoto, Japan

TSMC’s Kumamoto plant in Japan represents a significant stride in the company’s global expansion strategy. The following details provide a deeper insight into the progress and key features of this cutting-edge semiconductor fabrication facility:

Advanced Process Technologies: The Kumamoto plant is set to utilize advanced semiconductor process technologies, specifically the 12/16-nanometer and 22/28-nanometer nodes.

These process technologies are known for their versatility and efficiency, making them suitable for a wide range of applications, from consumer electronics to automotive systems.

Local Employment: TSMC’s commitment to boosting the local workforce is evident in Kumamoto. The company has already hired approximately 800 local employees, demonstrating its dedication to not only expanding its global operations but also contributing to the local economy by providing job opportunities.

This strategic focus on local talent acquisition fosters a sense of community and alignment with regional goals.

Equipment Relocation:The equipment relocation at the Kumamoto plant highlights its rapid progress. It’s a crucial phase that signifies the shift from planning to execution, demonstrating TSMC’s commitment to meeting its goals on time.

Production Commencement: The timeline for production commencement at the Kumamoto facility is noteworthy.

TSMC aims to commence production by the end of 2024, showcasing efficient project management. This rapid progress highlights the company’s commitment to meeting the increasing demand for advanced semiconductors in Japan and Asia.

Read More: TSMC Abandons Plans for Most Advanced Chip Fab Amidst Local Protests

4. Longtan Park Phase 3

The absence of updates on the Phase 3 construction at the Longtan Park during TSMC’s recent earnings call suggests a potential shift in the company’s focus and strategy. Here are more details about this development:

Phase 3 Construction at Longtan Park:

Longtan Park, located in Taiwan, has been a key site for TSMC’s semiconductor manufacturing operations.

Phase 3 was expected to represent a significant expansion of the facilities at this location, supporting the company’s global production capacity.

However, the lack of updates on this phase during the earnings call is notable, as it indicates a shift in TSMC’s immediate priorities.

Continued Evaluation:

TSMC’s statement that it will continue to evaluate suitable construction locations implies that the company is reevaluating its expansion strategy.

This could mean that TSMC is considering different options and locations for its future manufacturing facilities.

The company’s expansion plans may now be focused more on overseas facilities rather than further expansion in Taiwan.

Global Expansion Strategy:

TSMC’s decision to potentially shift its focus to overseas facilities aligns with its broader global expansion strategy.

The company has been actively establishing semiconductor fabrication plants in various international locations, such as the United States, Germany, and Japan, to meet the rising global demand for advanced semiconductor technology.

This approach enables TSMC to diversify its manufacturing capabilities and minimize supply chain risks.

Market Considerations:

Market dynamics and customer demand could be influencing TSMC’s shift in focus.

The company may be tailoring its strategy to better serve these diverse markets in different regions while reducing the risk associated with concentrating operations in a single location.

Future Developments:

While TSMC did not provide updates on Longtan Park Phase 3 during the earnings call, it does not necessarily mean that the project has been canceled.

The company may revisit this expansion in the future or adapt its plans in response to changing market conditions and business strategies.

Read More: TSMC N3P To Outperform Intel 18A, Derailing Intel’s Foundry Leadership Plan by 2025

5. Nanjing, China

TSMC’s ability to continue its operations in Nanjing, China, and the ongoing process of obtaining “Validated End-User (VEU)” authorization reflect the company’s commitment to maintaining a global presence while adhering to international regulations. Here are more details about this noteworthy development:

Extension Waiver from BIS:

The extension waiver granted to TSMC by the US Department of Commerce’s Bureau of Industry and Security (BIS) is a critical aspect of this development.

Such waivers are essential for companies that operate in countries subject to export controls and trade restrictions, such as China.

Validated End-User (VEU) Authorization:

The process of obtaining “Validated End-User (VEU)” authorization is a significant step in ensuring compliance with international regulations.

VEU status is typically granted to trusted companies with a history of responsible and secure technology use. It allows for more streamlined and controlled exports, which is particularly important for companies operating in sensitive industries like semiconductor manufacturing.

TSMC’s pursuit of VEU status reflects its commitment to adhering to export control regulations.

Indefinite Exemption Expectation:

TSMC’s expectation of securing an indefinite exemption in the near future suggests that the company is actively engaging with regulatory authorities to ensure its long-term ability to operate in Nanjing, China.

This exemption would provide more stability and predictability for TSMC’s operations in the region, which is essential for planning and investment.

Global Presence:

TSMC’s commitment to maintaining a global presence is underlined by its continued operations in Nanjing, China.

The company recognizes the importance of serving a global customer base and contributing to the semiconductor supply chain on an international scale. By strategically operating in various regions, TSMC can better meet the diverse needs of its customers and partners.

Navigating Regulatory Challenges:

Operating in the semiconductor industry, especially in regions with export control regulations, presents unique challenges.

TSMC’s ability to navigate these challenges and maintain compliance with international trade and export regulations demonstrates its commitment to responsible and ethical business practices.

Read More: Intel Foundry, Even if Successful, Will Be Overshadowed by TSMC: Chang

Conclusion

TSMC’s global expansion strategy is well underway, with its semiconductor fabrication facilities in Phoenix, Dresden, and Kumamoto making significant progress. Despite the initial higher costs associated with overseas plants, TSMC remains focused on its commitment to serve a broader global market. The company’s dedication to cutting-edge technology and its ability to navigate complex international regulations positions it as a key player in the semiconductor industry’s future. The coming years will undoubtedly bring exciting developments in TSMC’s international operations, further shaping the semiconductor landscape.