Introduction

In the realm of modern technology, the semiconductor industry stands as a cornerstone, powering the devices and systems that drive our interconnected world. From smartphones and computers to automobiles and industrial machinery, semiconductors form the bedrock of innovation and progress. However, behind the sleek façade of cutting-edge gadgets lies a world of intense competition, staggering investments, and formidable challenges that define the semiconductor business.

1. High Capital Investment & High Risk:

Manufacturing in the semiconductor realm demands colossal investments.

TSMC’s $20 Billion Wafer Fab: The semiconductor industry demands massive investments, as evidenced by TSMC’s recent announcement. Such investments cover the construction of state-of-the-art facilities, acquisition of cutting-edge equipment, and ongoing research and development costs.

Need for High Production Volume: To recoup these investments, companies must achieve high production volumes. This means churning out thousands of wafers weekly, each fetching substantial prices in the market.

Intel’s Underutilized Fab: Instances like Intel’s underutilized fab highlight the risks inherent in technological innovation. Failed attempts to integrate new technologies directly impact a company’s bottom line. This underscores the delicate balance between risk and reward in the semiconductor industry.

These fabs come with exorbitant price tags, often in the billions of dollars, and require near-maximum capacity utilization to operate profitably. This necessitates a highly skilled workforce comprising technicians and PhD-level researchers adept in process development and advanced R&D.

2. Skill Requirements and Educational Deficiencies:

Manufacturing Complexity: Making a semiconductor chip is a very intricate process. It involves manipulating materials at the atomic level and takes months to complete for a single chip. This complexity requires not only advanced equipment but also a highly skilled workforce to operate and maintain it

Highly Skilled Workforce: Unlike conventional manufacturing industries, semiconductor fabs demand more than just assembly line workers. The intricate nature of semiconductor device physics, chemistry, circuit design, and computer engineering necessitates a workforce versed in a multitude of disciplines. Without a robust foundation in semiconductor research and education, developing countries struggle to bridge the knowledge gap required to sustain a semiconductor ecosystem.

Educational Deficiencies in Developing Nations: Many nations lack the educational infrastructure to cultivate the expertise required for semiconductor manufacturing. This creates a deficiency in the labor pool needed to sustain a semiconductor ecosystem.

Follow us on Linkedin for everything around Semiconductors & AI

3. Electricity and Water

Moreover, the challenges extend beyond human capital. Semiconductor fabs require a steady supply of electricity and clean water.

Electricity Consumption:

Energy-intensive Processes: Semiconductor manufacturing involves energy-intensive processes such as wafer fabrication, deposition, etching, and packaging.

Estimate: A medium-sized semiconductor fab might consume anywhere from 100 to 200 megawatt-hours (MWh) of electricity per day. Larger facilities with advanced technology nodes could require even more electricity.

Water Consumption:

Cleanroom Environment: Semiconductor fabs require cleanrooms with controlled humidity levels, which necessitates water for cooling and maintaining environmental conditions.

Estimate: Water consumption can vary widely depending on the fab’s technology and cooling systems. A rough estimate could range from 1,000 to 3,000 gallons of water per minute (GPM) for cooling purposes alone.

Read More: Apple to Invest Over $250 Million in Expanding Singapore Campus – techovedas

4. Design: Navigating Complexity and Uncertainty

Designing semiconductor chips is no less daunting. It necessitates a profound understanding of the manufacturing process to effectively translate system and logic designs into photomasks.

This intricate process often begins before the process is finalized, demanding foresight and adaptability. Developing a library of logic elements, crucial for the mapping process, requires significant time and resources. Moreover, the design phase is fraught with uncertainties, ranging from errors in logic mapping to market viability.

The gestation period of 1-2 years underscores the meticulousness demanded in semiconductor design. Yet, despite the meticulous planning, the possibility of scrapping a design worth millions looms large, highlighting the inherent risks.

Read More: Top 10Trillion-Dollar Companies in 2024 – techovedas

5. Geopolitics

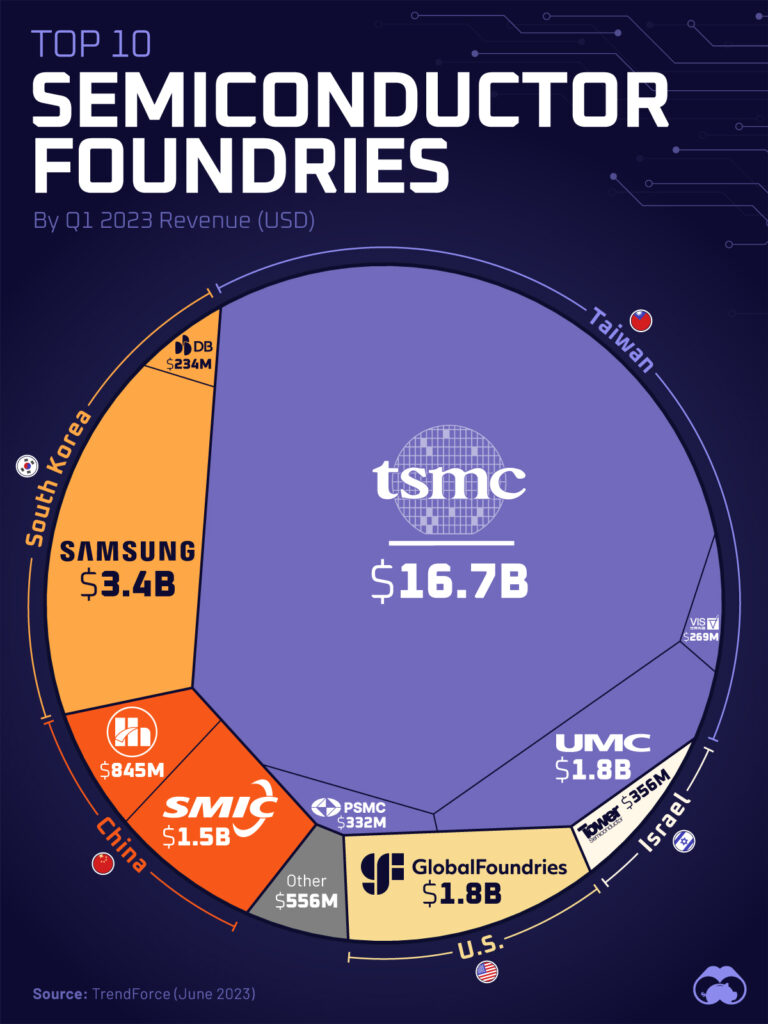

Concentration of Production: A small number of countries dominate different parts of the chip-making process. The US leads in chip design, but relies heavily on Taiwan and South Korea for manufacturing, and Japan for materials and equipment. This makes the supply chain vulnerable to disruptions in any of these regions.

Trade Tensions: Rising tensions between countries, particularly the US and China, can lead to trade restrictions and limitations on technology transfers. This can disrupt supply chains and make it harder for companies to access the materials and expertise they need.

National Security Concerns: Semiconductors are crucial for modern militaries, so governments are increasingly concerned about ensuring a reliable domestic supply. This can lead to government subsidies and protectionist policies that distort the market.

These geopolitical factors make it difficult for companies to plan for the long term and can lead to sudden shortages or price fluctuations.

Then why?

So, why do individuals and corporations continue to invest in this high-stakes industry? The answer lies in the promise of unparalleled rewards. The sheer scale of demand, exemplified by the sale of 1.5 billion smartphones and 350 million PCs in 2018 alone, presents a tantalizing opportunity.

Securing even a fraction of these markets can transform a semiconductor company into a veritable money-making machine. Companies like TSMC, supplying cutting-edge chips to tech giants like Apple, exemplify the immense potential for profitability in this arena.

It can be highly valuable to semiconductor companies grappling with testing complexities.

Read more 10 Fabrication Steps to Build a Semiconductor Chip – techovedas

Innovation and Resilience: The Heart of the Semiconductor Industry

Beyond the allure of profits, the semiconductor industry is a testament to the human spirit of innovation and resilience. It attracts individuals and organizations who thrive on the edge, relishing the challenges and uncertainties inherent in this ever-evolving landscape. The relentless pursuit of pushing the boundaries of what’s possible drives innovation, propelling humanity forward into uncharted technological territories.

Read More: Atmanirbhar Bharat in Action: Kaynes to Build RUDRA Supercomputers – techovedas

Conclusion: Forging the Future, One Transistor at a Time

In conclusion, the semiconductor industry represents a complex tapestry of manufacturing prowess, design intricacies, and unwavering determination. It is a realm where risk and reward coexist in delicate balance, where success hinges on the ability to navigate uncertainty and adversity. Yet, for those daring enough to venture into its depths, the rewards can be nothing short of transformative. It is a realm where dreams are woven into silicon, and where the future is forged one transistor at a time.

In conclusion, while the allure of semiconductor manufacturing may be tantalizing, the myriad complexities and challenges inherent in the industry present formidable barriers to entry for developing countries. Without the requisite human capital, infrastructure, and geopolitical stability, the dream of establishing a thriving semiconductor ecosystem remains a distant reality. As the semiconductor industry continues to push the boundaries of innovation, it serves as a poignant reminder of the intricate interplay between technology, education, and geopolitics on the global stage.