Introduction:

The semiconductor industry has been rapidly advancing, with continuous efforts to shrink the size of transistors and enhance the performance of integrated circuits through a term called Process node.

This progress is often denoted by the term “process nodes,” such as 10nm, 7nm, 5nm, 3nm, and the cutting-edge 2nm.

However, these numbers are not just marketing terms; they represent the dimensions of key components in semiconductor fabrication.

In this blog post, we will delve into the intricacies of process nodes, focusing on the approximate transistor area for each.

Follow us on Linkedin for everything around Semiconductors & AI

Understanding Process Nodes:

Process nodes refer to the manufacturing technology used to create integrated circuits, specifying the size of individual transistors and other components on a chip.

Smaller process nodes enable more transistors to be packed into a given area, leading to increased performance, reduced power consumption, and enhanced efficiency.

Process nodes play a crucial role in the semiconductor industry and have significant implications for the design and manufacturing of integrated circuits (ICs). Here are some key aspects that highlight the significance of process nodes:

Transistor Density:

- The primary impact of advancing to smaller process nodes is the increased transistor density on a chip. As the dimensions of transistors are reduced, more transistors can be accommodated in a given area. This allows for the integration of more complex and powerful circuits.

Performance Improvement:

- Higher transistor density directly translates to improved performance. With more transistors available, processors can execute more tasks simultaneously, leading to increased computational power and faster processing speeds. This is particularly important for applications that demand high-performance computing, such as data centers, artificial intelligence, and advanced graphics.

Power Efficiency:

- Smaller transistors typically require less power to switch between states. As a result, moving to smaller process nodes contributes to improved power efficiency. This is critical for mobile devices, where energy conservation is a key factor in extending battery life.

Cost Reduction:

- While the initial development of a new process node can be expensive, the ability to produce more chips per silicon wafer due to increased transistor density can lead to cost savings per unit. This is especially important in high-volume manufacturing scenarios, such as consumer electronics.

Miniaturization:

- Smaller process nodes enable the miniaturization of electronic devices. This is essential for applications where space is a limiting factor, such as mobile phones, wearables, and Internet of Things (IoT) devices. Miniaturization also allows for the integration of more functionality into smaller form factors.

Innovation and New Features:

- Advanced process nodes provide the technological foundation for incorporating new features and innovations into semiconductor devices. This includes advancements in materials, manufacturing techniques, and design methodologies that enable the development of cutting-edge technologies like 5G, AI accelerators, and high-performance computing architectures.

Competitive Edge:

- Semiconductor companies that lead in the development of smaller process nodes gain a competitive edge. Being at the forefront of technology allows for the production of more advanced and efficient chips, attracting customers who seek the latest in performance and efficiency.

Challenges and Innovations:

- Shrinking process nodes also pose challenges in terms of manufacturing complexity, heat dissipation, and the use of new materials. Overcoming these challenges requires continuous innovation in semiconductor manufacturing techniques, materials science, and design methodologies.

In summary, process nodes are a critical factor in the evolution of semiconductor technology, influencing the performance, efficiency, and form factor of electronic devices. Advances in process nodes drive innovation and enable the development of more powerful and energy-efficient integrated circuits.

Read More: The Ultimate Semiconductor Process Integration Quiz Journey

Transistor Area for Various Process Nodes:

a. 10nm Process (64×45) nm:

The 10nm process represents a significant advancement in semiconductor technology. Transistors at this node have approximate dimensions of 64×45 nanometers. The reduced size allows for higher transistor density, contributing to improved performance and energy efficiency in electronic devices.

b. 7nm Process (57×38) nm:

A further refinement in fabrication technology, the 7nm process, brings transistors down to approximately 57×38 nanometers. This reduction in size enables more transistors to be placed on a chip, resulting in enhanced computational power and energy efficiency.

c. 5nm Process (48×32) nm:

The 5nm process takes miniaturization a step further with transistors measuring approximately 48×32 nanometers. This level of precision allows for even greater transistor density, facilitating the development of more powerful and energy-efficient electronic devices.

d. 3nm Process (39×26) nm:

As we enter the 3nm process node, transistors become even smaller, measuring around 39×26 nanometers. The reduction in size comes with challenges, including increased manufacturing complexity and the need for advanced materials and techniques.

e. 2nm Process (30×20) nm:

At the forefront of semiconductor technology, the 2nm process represents a remarkable achievement in miniaturization. Transistors at this node are estimated to have dimensions of approximately 30×20 nanometers, pushing the boundaries of what is physically possible in semiconductor fabrication.

Read More: Happy 65th Birthday, Integrated Circuit! Thank You, Jack Kilby – techovedas

Moore’s Law:

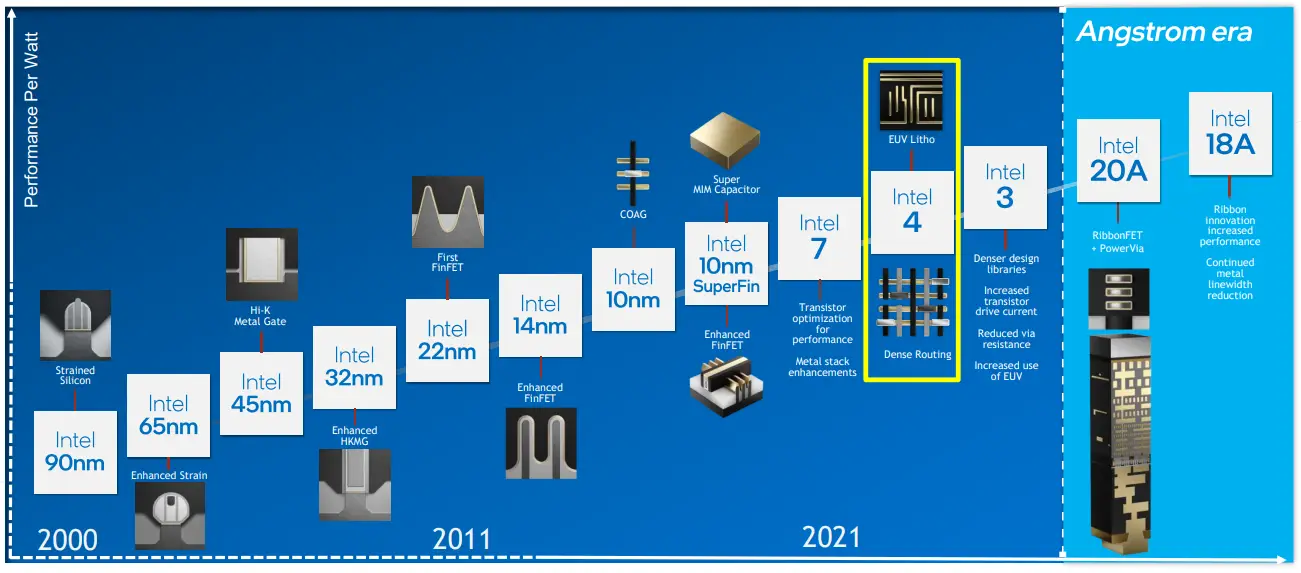

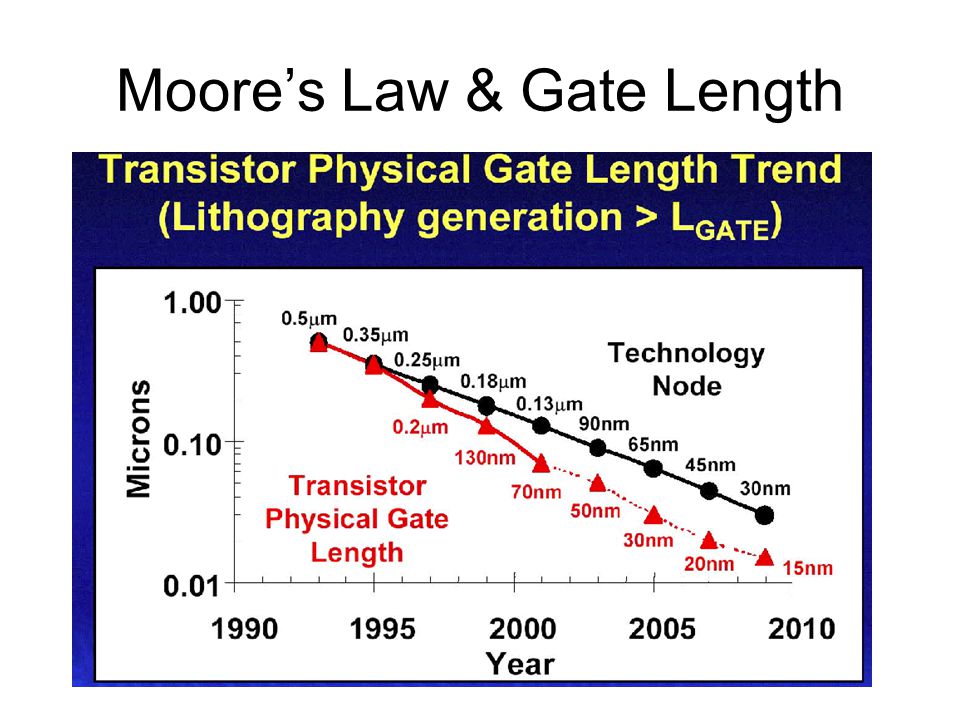

Moore’s Law is an observation made by Gordon Moore, co-founder of Intel, in 1965. He predicted that the number of transistors on a microchip would double approximately every two years, leading to a continuous increase in computing power and a decrease in the cost per transistor. Over the years, this observation has held true, although the timeline for doubling has varied. The essence of Moore’s Law is the exponential growth in the number of transistors on a chip, enabling a corresponding increase in computational performance.

Relationship with Process Nodes:

The advancement described by Moore’s Law is often closely tied to the shrinking of semiconductor process nodes. A process node refers to the manufacturing technology used to create integrated circuits, specifying the size of individual transistors and other components on a chip. As process nodes decrease in size, more transistors can be packed into a given area, aligning with the predictions of Moore’s Law.

Implications of Smaller Process Nodes:

a. Increased Performance: Smaller transistors allow for higher transistor density, leading to increased computational power and faster processing speeds.

b. Improved Energy Efficiency: The reduction in transistor size contributes to lower power consumption, making electronic devices more energy-efficient and extending battery life in portable devices.

c. Challenges in Manufacturing: Shrinking process nodes pose manufacturing challenges, including the need for advanced lithography techniques, new materials, and precise control over the fabrication process.

| Process Node | Transistor Area (nm²) | % Change vs. Previous Node |

|---|---|---|

| 10nm | (64×45) | – |

| 7nm | (57×38) | -10.94% |

| 5nm | (48×32) | -15.79% |

| 3nm | (39×26) | -18.75% |

| 2nm | (30×20) | -23.08% |

Read More: How Well do you know Nvidia- Take Our Quiz to Find out

Conclusion:

In conclusion, the progression of semiconductor technology, as indicated by process nodes, has a profound impact on the capabilities of electronic devices.

The continuous push for smaller transistors not only enhances performance and energy efficiency but also presents significant challenges to semiconductor manufacturers.

As we look towards the future, the exploration of even smaller process nodes will undoubtedly shape the landscape of electronics, enabling innovations that were once thought impossible.