Introduction:

In the ever-evolving landscape of technology, the race to create smaller, faster, and more efficient electronic devices is relentless. At the heart of this pursuit lies a pivotal aspect—advanced packaging in semiconductor technology.

This unsung hero plays a crucial role in shaping the future of electronics by unlocking a myriad of benefits, ranging from miniaturization to enhanced functionality and reliability.

Follow us on LinkedIn for everything around Semiconductors & AI

What is advanced packaging?

Let’s use an analogy of packing for a camping trip to explain the difference between existing packaging and advanced packaging in chips.

Imagine you’re getting ready for a camping trip, and you need to pack your supplies. You have two options for packing: standard packaging and advanced packaging.

- Standard Packaging: In standard packaging, you use basic containers like plastic bins and cardboard boxes to pack your supplies. You organize your items somewhat efficiently, but there’s a lot of wasted space in the containers. Moreover, this means you might need to take multiple trips to carry all your gear, and it can be cumbersome to carry everything around the campsite.

- Advanced Packaging: With advanced packaging, you use specialized storage solutions like vacuum-sealed bags and collapsible containers. Additionally, these containers are designed to maximize space efficiency, allowing you to fit more gear into a smaller area. You can pack everything neatly and compactly, making it easier to carry and transport your supplies to the campsite in a single trip.

Now, let’s relate this analogy to chip packaging:

- Existing Packaging: Similar to standard packaging, existing chip packaging methods use conventional techniques to arrange components on the chip. While these methods work well for basic functionality, they are limited in terms of space efficiency and performance optimization. Chips may be larger, less power-efficient, and have limited functionality compared to what advanced packaging can offer.

- Advanced Packaging: Just like advanced camping packaging, advanced chip packaging techniques utilize specialized methods to arrange and connect components more efficiently. Moreover, this allows for the creation of smaller, more powerful, and energy-efficient chips. By reducing wasted space, minimizing signal delays, and optimizing thermal management, advanced packaging enables chips to perform better, consume less power, and integrate more functions into a smaller space.

So, just as advanced packaging revolutionizes how efficiently you can pack for a camping trip, it also revolutionizes how efficiently electronic components can be packed onto a chip, leading to better performance, lower power consumption, and more compact devices.

Read More: What are 5 Techniques in Advanced Packaging?

5 Reasons We need Advanced Packaging for Chips

1. Miniaturization: Shrinking the World of Electronics

One of the driving forces behind the need for advanced packaging is the constant quest for miniaturization. As technology advances, the demand for smaller and more compact electronic devices grows. Its techniques pave the way for the integration of a higher number of components into a reduced space, facilitating the creation of devices that are not only smaller but also more powerful.

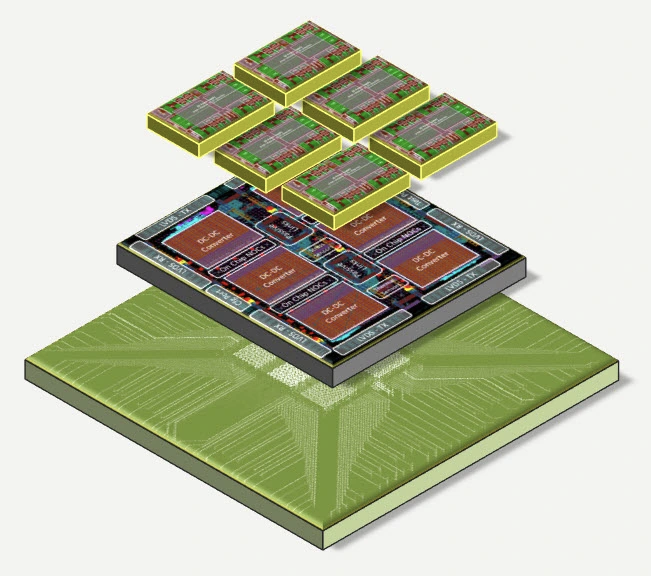

Imagine you have a smartphone with advanced packaging technology. Moreover,Traditional packaging might require separate chips for the processor, memory, and graphics processing unit (GPU), taking up significant space on the device’s motherboard. However, withitstechniques like 3D integration or chip stacking, these components can be integrated into a single chip, reducing the overall footprint of the device. This allows for sleeker designs and more compact devices without compromising on performance.

Read More: Why TSMC Wants OSAT partners to Expand Advanced Packaging ?

2. Performance Boost: Overcoming Signal Delays and Thermal Challenges

Advanced packaging acts as a catalyst for improving chip performance on multiple fronts. By strategically placing components closer together and leveraging specialized materials, it addresses the perennial challenges of signal delays and thermal management. This optimization results in a significant increase in the speed and efficiency of data transfer within the chip, unlocking new levels of performance previously deemed unattainable.

Consider a high-performance computing application where low latency and high-speed data transfer are critical. Its techniques such as through-silicon vias (TSVs) and silicon interposers enable shorter interconnects between components, reducing signal delays and improving overall performance. Additionally, advanced thermal management solutions like microfluidic cooling or embedded heat sinks ensure that the chip operates at optimal temperatures, further enhancing its performance under demanding workloads.

Read More: CoWoS: TSMC’s New Secret Weapon for Advanced Packaging

3. Power Efficiency: Reducing Travel Distance for Signals

Efficient power management is a cornerstone of electronic device design.Its techniques contribute to this endeavor by reducing the distance that signals need to travel within the chip. This not only minimizes power consumption but also optimizes the layout of components, leading to chips that are not only powerful but also energy-efficient.

In the context of a battery-powered device like a laptop, power efficiency is paramount to prolonging battery life. However, Its techniques can help achieve this by reducing the distance signals need to travel within the chip, minimizing power consumption. Moreover, optimized layouts and materials with lower resistance and capacitance contribute to lower power dissipation, resulting in energy-efficient devices that last longer on a single charge.

Read More: 3 Course to Master Chip Packaging from Basic to Advanced in 24 hours

4. Functionality Integration: A Symphony of Capabilities in a Single Chip

One of the most remarkable aspects of advanced packaging is its ability to enable the integration of diverse functions into a single chip. Additionally ,this multifunctional prowess allows for the creation of highly integrated devices, paving the way for cost savings and improved reliability and manufacturability. In essence, advanced packaging turns a chip into a versatile powerhouse, capable of handling a multitude of tasks seamlessly.

Suppose you have a smartwatch packed with its technology. By integrating various sensors, processors, and wireless communication modules into a single chip using Its techniques like system-in-package (SiP) or system-on-chip (SoC), the device can offer a wide range of functionalities in a compact form factor. This seamless integration not only enhances user experience but also reduces manufacturing complexity and costs.

Read More: What are the Various Types of Semiconductor Packaging

5. Reliability and Durability: Building Robust Foundations

Advanced packaging techniques go beyond performance enhancements; they actively contribute to the reliability and durability of chips. By addressing thermal management challenges and minimizing the risk of signal interference, these techniques enhance the overall robustness of chips. This results in longer lifespans for electronic devices and a significant reduction in failures, ensuring a more reliable user experience.

Consider a mission-critical application like automotive electronics, where reliability is non-negotiable.Its techniques play a crucial role in ensuring the longevity and robustness of chips in harsh operating conditions. For instance, under-the-hood automotive chips may employ advanced packaging with enhanced thermal dissipation and ruggedized materials to withstand extreme temperatures and vibrations, thereby minimizing the risk of failures and ensuring the safety and reliability of the vehicle.

Read More: Amkor to Invest $1.6 Billion in Vietnam for Packaging & Assembly

Conclusion: The Future Unveiled

In conclusion, advanced packaging stands as a cornerstone in the relentless pursuit of advancing semiconductor technology. Its multifaceted contributions, from miniaturization and enhanced performance to power efficiency, functionality integration, and improved reliability, collectively propel the electronics industry forward. As we continue to witness the evolution of electronic devices, it is evident that advanced packaging will remain a driving force, shaping the future of smaller, faster, and more efficient technologies.