Introduction

In the ever-evolving landscape of technology, semiconductor devices lie at the heart of virtually every electronic system we encounter. Semiconductors form the fundamental building blocks of modern electronics, powering everything from smartphones to supercomputers. In this guide, we explore the key terms and technologies behind semiconductor engineering. We’ll shed light on the intricate processes involved in creating the devices shaping our digital world.

Follow us on Linkedin for everything around Semiconductors & AI

13 Semiconductor Terms Everyone MUST Know

1. Semiconductor

At the core of semiconductor technology lies the material itself. Semiconductors are materials with electrical conductivity levels between those of conductors and insulators. This unique property allows them to selectively conduct electrical currents, making them ideal for use in electronic devices.

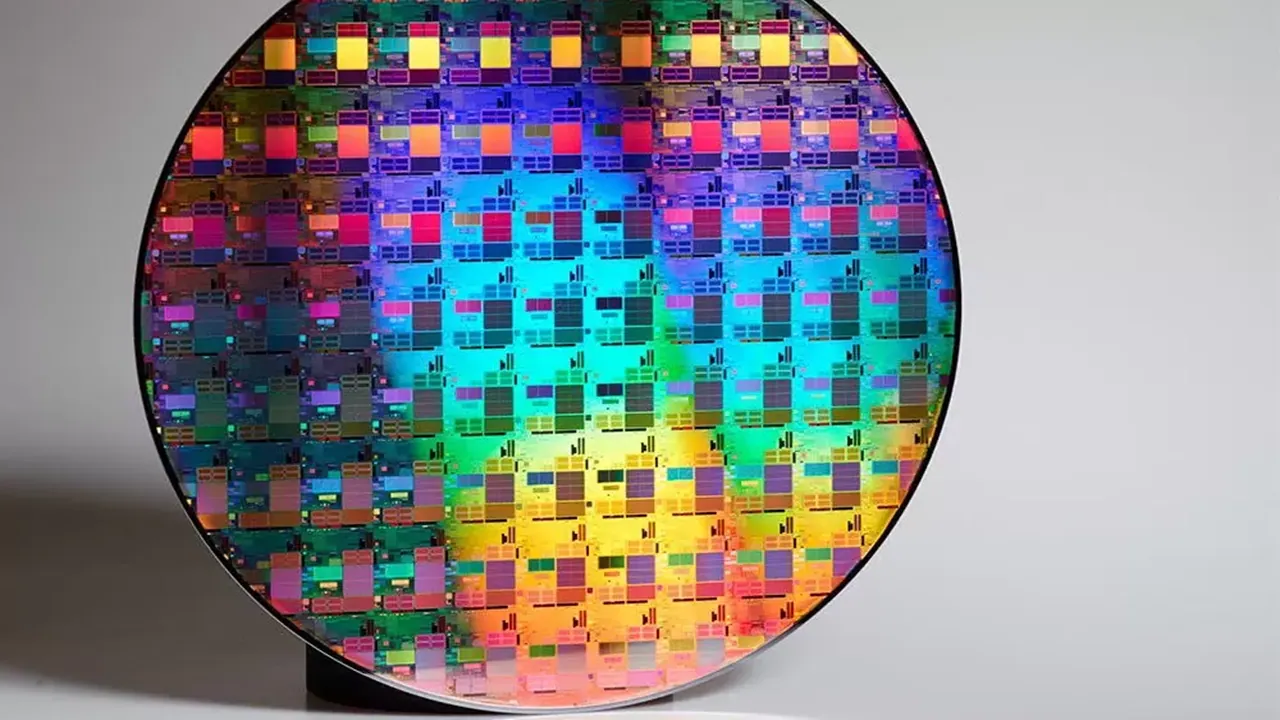

Silicon (Si) is the most widely used semiconductor material in the electronics industry due to its abundance and suitable properties. Silicon wafers serve as the canvas upon which integrated circuits are fabricated. These thin slices of semiconductor material, typically made from silicon, undergo a series of intricate processes to transform them into functional microchips.

Test your semiconductor Knowledge with our free Quizzes here

2. Transistor

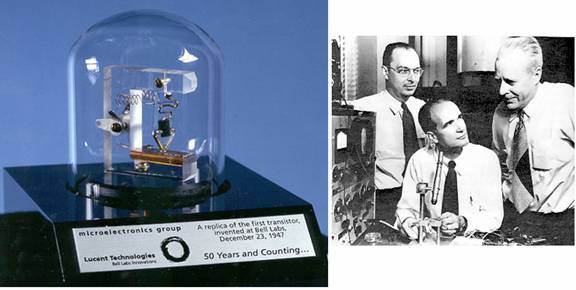

Arguably one of the most transformative inventions of the 20th century, the transistor revolutionized electronics by serving as a key component for amplifying and switching electronic signals. Its invention paved the way for the miniaturization of electronic devices and laid the foundation for the integrated circuits that followed.

First Transistor Ever

The MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) is one of the most common types of transistors used in integrated circuits. It’s found in almost every digital electronic device, such as microprocessors and memory chips.

3. Integrated Circuit (IC)

Integrated circuits, often referred to as microchips, are the epitome of semiconductor technology. Engineers etch these complex assemblies of electronic components onto a small flat piece of semiconductor material, enabling the creation of highly functional electronic systems in a compact form factor.

The Intel 4004, released in 1971, was one of the earliest microprocessors and an example of an integrated circuit. It combined all the functions of a central processing unit (CPU) onto a single chip.

Want to know the journey of a chip from concept to Execution, click here

4. Diode

Diodes are semiconductor devices that allow current to flow in one direction only. Widely used as rectifiers in power supplies and as switching elements in electronic circuits, diodes play a crucial role in directing the flow of electrical currents within electronic systems.

The 1N4148 is a commonly used small-signal diode. It allows current to flow in one direction only and is often used in signal processing and power supply circuits.

5. CMOS (Complementary Metal-Oxide-Semiconductor)

CMOS technology represents a cornerstone of modern integrated circuit design. Renowned for its low power consumption and high noise immunity, CMOS technology is ubiquitous in digital circuits, powering everything from microprocessors to memory chips.

The STM32 microcontroller series by STMicroelectronics utilizes CMOS technology. These microcontrollers are used in a wide range of applications, including IoT devices, automotive systems, and consumer electronics.

Learn about the history of Semiconductor Industry here

6. Fabrication Process

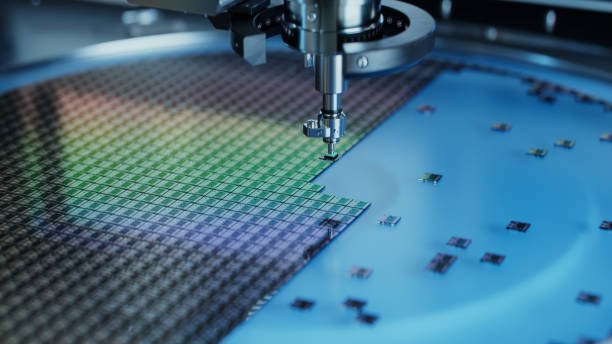

The fabrication process encompasses a series of meticulously orchestrated steps aimed at creating integrated circuits on semiconductor wafers. From deposition and lithography to etching and doping, each stage of the process plays a crucial role in shaping the final functionality and performance of the resulting microchips.

The 7nm (nanometer) fabrication process, used by companies like AMD and Apple for their latest CPU and GPU designs, involves intricate steps such as photolithography, etching, and ion implantation to create densely packed and high-performance semiconductor chips.

7. Moore’s Law

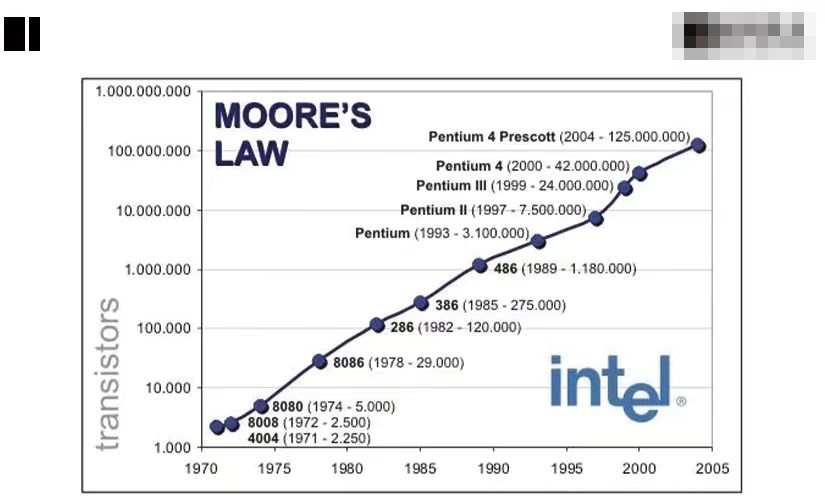

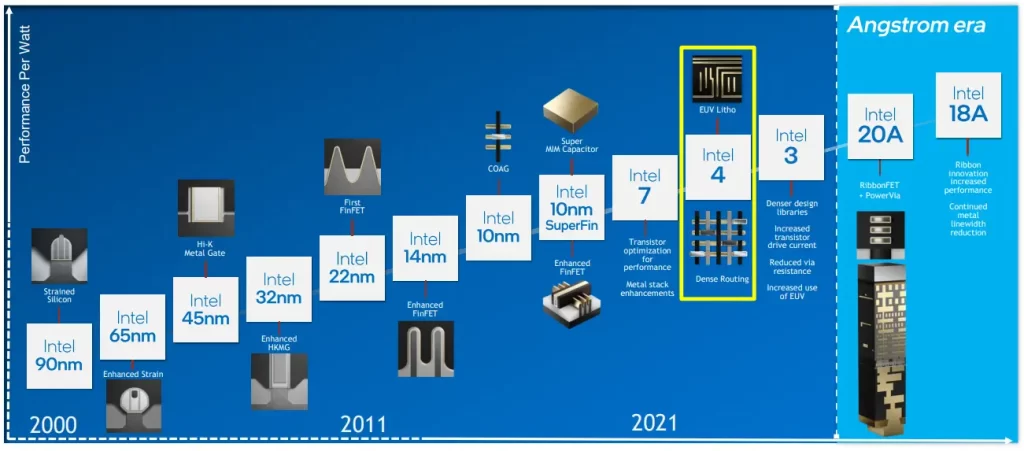

Moore’s Law, although not a physical law, has served as a guiding principle for the semiconductor industry for several decades. This empirical observation predicts that the number of transistors on a microchip doubles approximately every two years, driving continuous advancements in computing power, cost reduction, and miniaturization.

Historically, Intel’s CPU generations have followed Moore’s Law, with each new generation doubling the number of transistors on a chip approximately every two years. For example, the transistor count in Intel’s CPUs has increased from thousands in the 1970s to billions in recent years.

What does life of a semiconductor engineer look like, read here

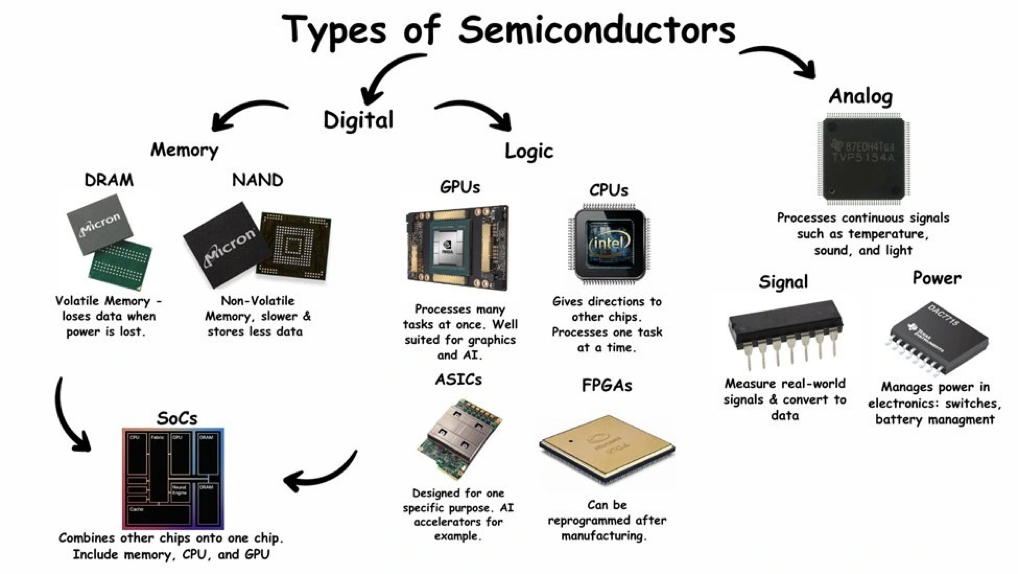

8. Logic, Memory and Analog Chips

Logic chips process digital signals using Boolean logic functions, memory chips store and retrieve digital data efficiently, and digital analog chips bridge the gap between digital and analog domains, enabling the processing and conversion of signals between these two realms.

Together, these semiconductor devices form the Foundation of modern electronic systems, powering everything from computers and smartphones to complex industrial automation and communication networks.

9. VLSI (Very Large Scale Integration)

VLSI technology represents the pinnacle of semiconductor integration. This enables the creation of complex electronic systems by integrating thousands or even millions of transistors onto a single chip. This technology has revolutionized industries ranging from telecommunications to automotive electronics, empowering the development of innovative and feature-rich electronic devices.

The NVIDIA GeForce RTX 30 Series GPUs, based on Ampere architecture, are examples of VLSI chips. They contain millions of transistors packed into a single chip, enabling high-performance graphics rendering for gaming and professional applications.

Learn about stalwarts of semiconductor revolution here

10. Process Node

The term “process node” refers to the size of the smallest feature that can be created on a semiconductor chip during the manufacturing process. Measured in nanometers, process nodes signify the level of miniaturization achieved in semiconductor fabrication. Smaller process nodes enable the production of chips with higher performance, lower power consumption, and reduced manufacturing costs, driving the relentless march of technological progress.

The TSMC 5nm process node, used for manufacturing chips like Apple’s A14 Bionic processor, features transistor sizes as small as 5nm. This allows for increased performance and energy efficiency compared to previous generations.

11. Assembly

Semiconductor assembly involves the integration of individual semiconductor components into functional electronic systems. This process encompasses die attach, wire bonding, encapsulation, and other techniques aimed at ensuring the reliability and performance of the final product.

Advanced assembly technologies, such as flip-chip bonding and wafer-level packaging, enable the creation of compact, high-performance devices suited for a wide range of applications.

Read about the Artificial Intelligence Revolution here

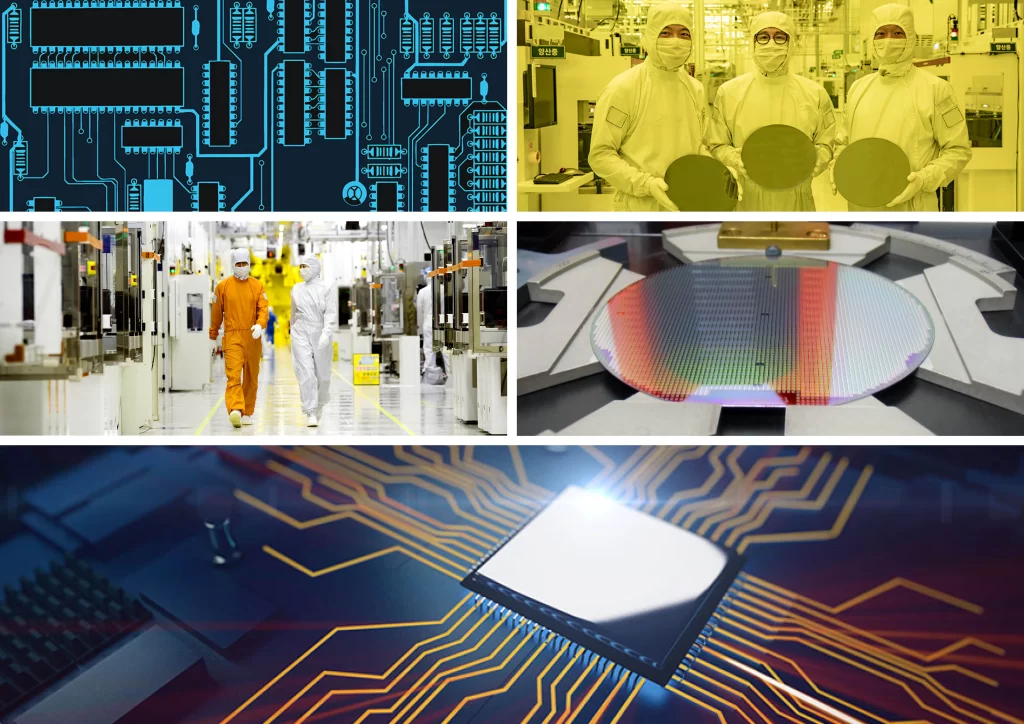

12. Fab (Fabrication)

Semiconductor fabrication, often referred to as “Fab,” encompasses the complex series of processes involved in creating integrated circuits on semiconductor wafers. These processes include photolithography, etching, deposition, doping, and more, each meticulously orchestrated to achieve precise control over device geometry and electrical properties.

Advanced fabrication facilities, equipped with state-of-the-art equipment and cleanroom environments, enable the production of cutting-edge semiconductor devices with nanometer-scale features.

13. OSATs (Outsourced Semiconductor Assembly and Test)

OSATs play a pivotal role in the semiconductor supply chain, providing essential services such as packaging, testing, and logistics. As semiconductor manufacturing has become increasingly specialized and capital-intensive, many companies opt to outsource assembly and testing processes to OSATs.

These specialized firms leverage economies of scale and expertise to deliver high-quality, cost-effective solutions. This enables semiconductor companies to focus on core competencies such as design and fabrication.

Conclusion

From the humble beginnings of the transistor to the intricate complexities of VLSI design, the evolution of semiconductor engineering continues to push the boundaries of what’s possible in the realm of electronics.